How Do You Choose the Right Decoiler Capacity for Steel Coils (3-10 Tons)

- Share

- Issue Time

- Sep 16,2025

Summary

Learn how to select the ideal decoiler/uncoiler capacity for 3-10 ton steel coils. Discover Fanty’s expert solutions and tips to optimize your metal processing line.

By Fanty Experts | Published: September 15, 2025

Selecting the right Decoiler, or uncoiler, capacity is crucial for efficient metal processing, especially when handling steel coils weighing 3-10 tons. A mismatched decoiler can lead to downtime, material waste, or safety issues. In this guide, we’ll break down the key factors to consider, drawing on industry insights from sources. At Fanty, with over 13 years of expertise in metal stamping automation, we offer tailored decoiler solutions to ensure seamless integration and optimal performance in your production line.

Understanding Decoiler/Uncoiler Capacity

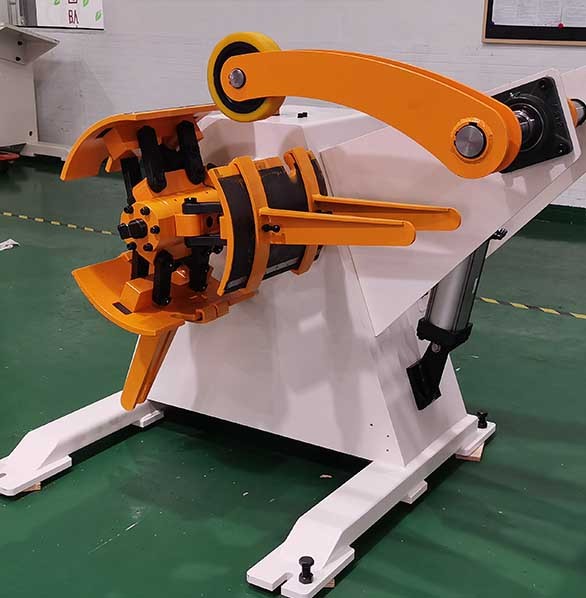

Decoiler/uncoiler capacity refers to the maximum coil weight the machine can handle safely and efficiently. For steel coils in the 3-10 ton range, common in automotive, construction, and HVAC industries, capacities typically range from 3 tons (manual or motorized) to 10 tons (hydraulic models). This ensures stable unwinding without overloading the mandrel or drive system. Fanty’s decoilers, such as our motorized MT-800 series, are designed for this range, supporting coil weights up to 5-10 tons with precise tension control.

Key Factors to Consider When Choosing Capacity

To match a decoiler/uncoiler to your 3-10 ton steel coils, evaluate these essential factors based on industry standards:

1. Coil Weight and Material

Ensure the decoiler’s rated capacity exceeds your coil’s weight by 10-20% for safety. For steel coils (including AHSS), motorized decoilers handle 3-10 tons effectively, while hydraulic models excel for heavier or high-tensile materials. Fanty recommends hydraulic expansion for coils over 5 tons to prevent slippage.

2. Coil Dimensions (Width, ID/OD)

Check inner diameter (ID: 450-530mm typical) and outer diameter (OD: up to 1200mm). Widths of 300-1000mm suit most 3-10 ton applications. Fanty’s customizable decoilers adjust for widths up to 2000mm, ensuring compatibility with your steel coils.

3. Material Thickness and Type

For steel thicknesses of 0.8-6.0mm, add a pressing arm if over 2mm to avoid uncoiling issues. Hydraulic models from Fanty provide superior control for thicker, flexible steels.

4. Production Speed and Volume

High-volume lines need motorized or hydraulic decoilers with VFD speed control. For 3-10 ton coils, aim for models integrating with straighteners and feeders to maintain consistent feed rates.

5. Space and Budget Constraints

Compact facilities benefit from pallet decoilers (1-5 tons), while budgets favor manual options for lighter loads. Fanty’s solutions balance cost with ROI through efficiency gains of 20-40%.

Types of Decoilers for 3-10 Ton Steel Coils

For this capacity range, motorized and hydraulic decoilers are ideal:

- Motorized Decoilers: Best for 3-10 tons, with electric motors for consistent unwinding. Fanty’s MT series offers optional coil cars for easy loading.

- Hydraulic Decoilers: For heavier 5-10 ton coils, providing mandrel expansion and superior tension. Include pressing arms for safety, as recommended by Henli.

Fanty: Your Expert Partner for Decoiler Solutions

Since 2013, Fanty has been a leader in metal coil processing equipment, with a 45,000㎡ facility in Dongguan and over 80 R&D experts. Our decoilers, like the 3-in-1 Straightener-Feeder-Decoiler, are customized for 3-10 ton steel coils, ensuring precision and efficiency. Backed by CE certification and world-brand components, we deliver reliable solutions globally.

Case Study: An automotive manufacturer upgraded to Fanty’s 5-ton motorized decoiler, reducing setup times by 25% and waste by 15%. Read more success stories.

Frequently Asked Questions

What capacity decoiler do I need for a 5-ton steel coil?

Opt for a 5-10 ton motorized or hydraulic model. Fanty’s MT-800 handles this with ease, including customizable ID/OD adjustments.

Should I choose manual or hydraulic for 3-10 ton coils?

Hydraulic for heavy-duty precision; manual for lighter, low-volume tasks. Fanty offers both with safety features.

Conclusion

Choosing the right decoiler/uncoiler capacity for 3-10 ton steel coils involves balancing coil specs, production needs, and budget. By focusing on these factors, you can enhance efficiency and reduce costs. Fanty’s innovative decoilers, backed by over a decade of expertise, provide customized solutions to meet your requirements. Contact us for a free consultation or integration plan.

Download Our Decoiler Selection Guide

About Fanty

Fanty is a global leader in coil processing equipment, delivering innovative solutions like decoiler machines, NC Servo Feeders, and 3-in-1 systems. With over 10 years of experience since 2013, we provide reliable, customized machinery and 24/7 support to manufacturers worldwide. Learn more at decoilerfeeder.com.