How Is Coil Processing Equipment Transforming Manufacturing in 2025?

- Share

- Issue Time

- Jul 10,2025

Summary

Discover how coil processing equipment is transforming manufacturing in 2025 with expert insights from Fanty.

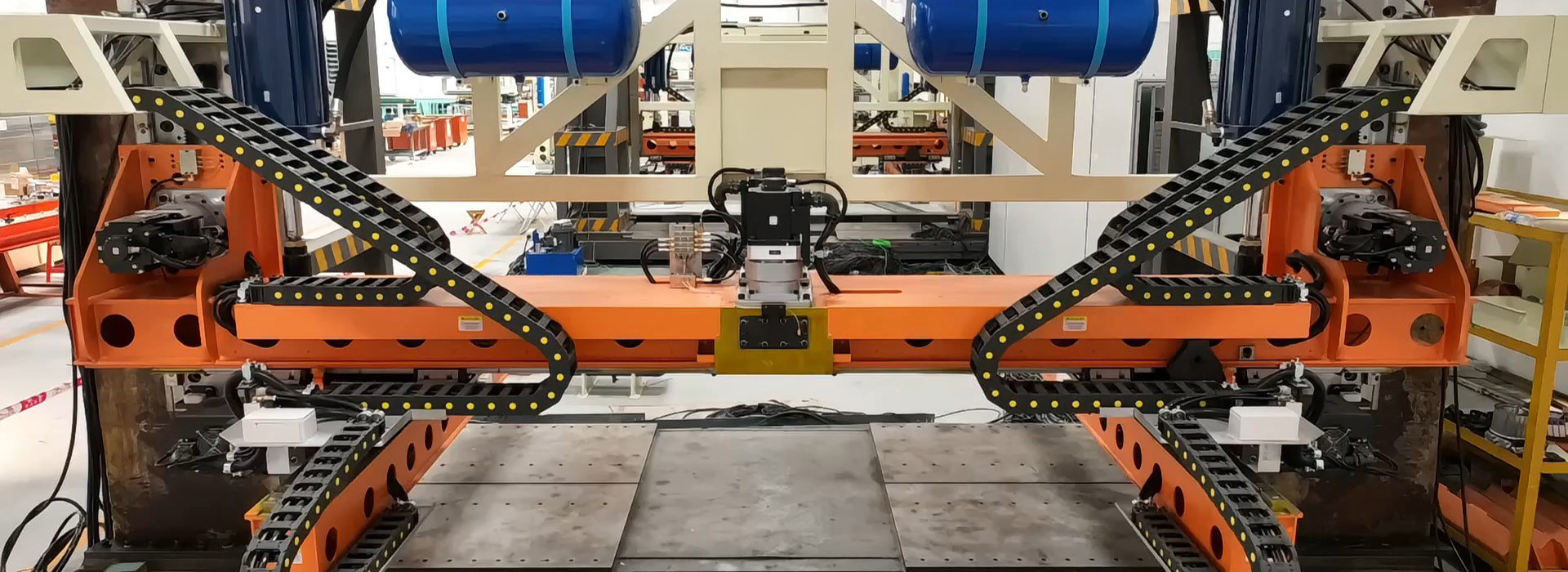

As we navigate the manufacturing landscape of 2025, coil processing equipment stands out as a game-changer, revolutionizing how industries handle steel coils to produce sheets, strips, and blanks. This technology is critical for sectors like automotive, construction, and appliances, driving efficiency and innovation. Fanty, a pioneering manufacturer of metal coil processing equipment since 2013, has been instrumental in this transformation, offering advanced solutions such as decoiler, straightener, feeders and stamping machine. With a team of 81 R&D professionals, Fanty is dedicated to shaping the future of metal processing. This guide explores how steel coil processing equipment is transforming manufacturing in 2025, with a focus on its technological leaps, industry impact, and Fanty’s contributions.

The Evolution of Coil Processing Technology

Coil processing equipment has evolved from basic manual systems to sophisticated automated lines, reflecting the industry’s push for precision and speed. Fanty’s journey since 2013 has paralleled this growth, introducing equipment that handles 5-35 ton coils with unmatched accuracy, serving global markets from automotive to renewable energy.

Transformative Features of Modern Equipment

Modern coil processing equipment is redefining production with these key features:

- High-Speed Automation

- Fanty’s automated lines reduce cycle times by up to 25%, enabling faster output for high-demand sectors.

- Precision Cutting and Leveling

- Advanced laser and leveling technologies, a Fanty specialty, ensure flatness within 0.1mm, critical for quality products.

- Energy-Efficient Designs

- Fanty’s eco-friendly machines cut energy use by 15%, aligning with 2025 sustainability goals.

- Smart Integration

- IoT-enabled systems from Fanty allow real-time monitoring, boosting operational efficiency.

Impact Across Industries

Coil processing equipment is reshaping manufacturing sectors in 2025:

- Automotive: Supports EV component production with Fanty’s lightweight material solutions.

- Construction: Enhances structural steel processing with Fanty’s high-capacity lines.

- Appliances: Delivers precision for home goods, showcased by Fanty’s recent 20% efficiency boost for a client.

Fanty’s CE-certified coil processing equipment meets these diverse needs.

Innovations Driving the Transformation

The transformation hinges on these 2025 innovations:

- Laser Blanking Advances: Fanty’s laser lines cut complex shapes with 99% accuracy.

- Robotic Automation: Fanty integrates robots for material handling, reducing labor costs by 20%.

- Predictive Maintenance: Fanty’s AI systems predict failures, minimizing downtime.

- Customizable Solutions: Fanty offers tailored designs for niche markets.

Real-World Success Stories

Fanty’s impact is evident in these cases:

- Automotive Case: A 30% production increase with Fanty’s laser blanking.

- Construction Case: A 15% cost reduction using Fanty’s energy-efficient lines.

- Lessons Learned: Adaptability and support are key, areas where Fanty excels.

Fanty’s Role in the Transformation

Fanty, based in guangdong province, China, has led since 2013 with over half of our 81 R&D professionals boasting 10+ years of experience. Our CE certificate coil processing equipment, including decoiler, straightener, feeders, serve global industries. Contact us at [sales@sz-fanty.com] to join the 2025 revolution.

Conclusion

Coil processing equipment is transforming manufacturing in 2025 through automation, precision, and sustainability. With Fanty’s innovative solutions, you can lead this change. Explore our offerings today.