How To Keep Your Coil Processing Equipment Running Smoothly ?

- Share

- Issue Time

- Jul 24,2025

Summary

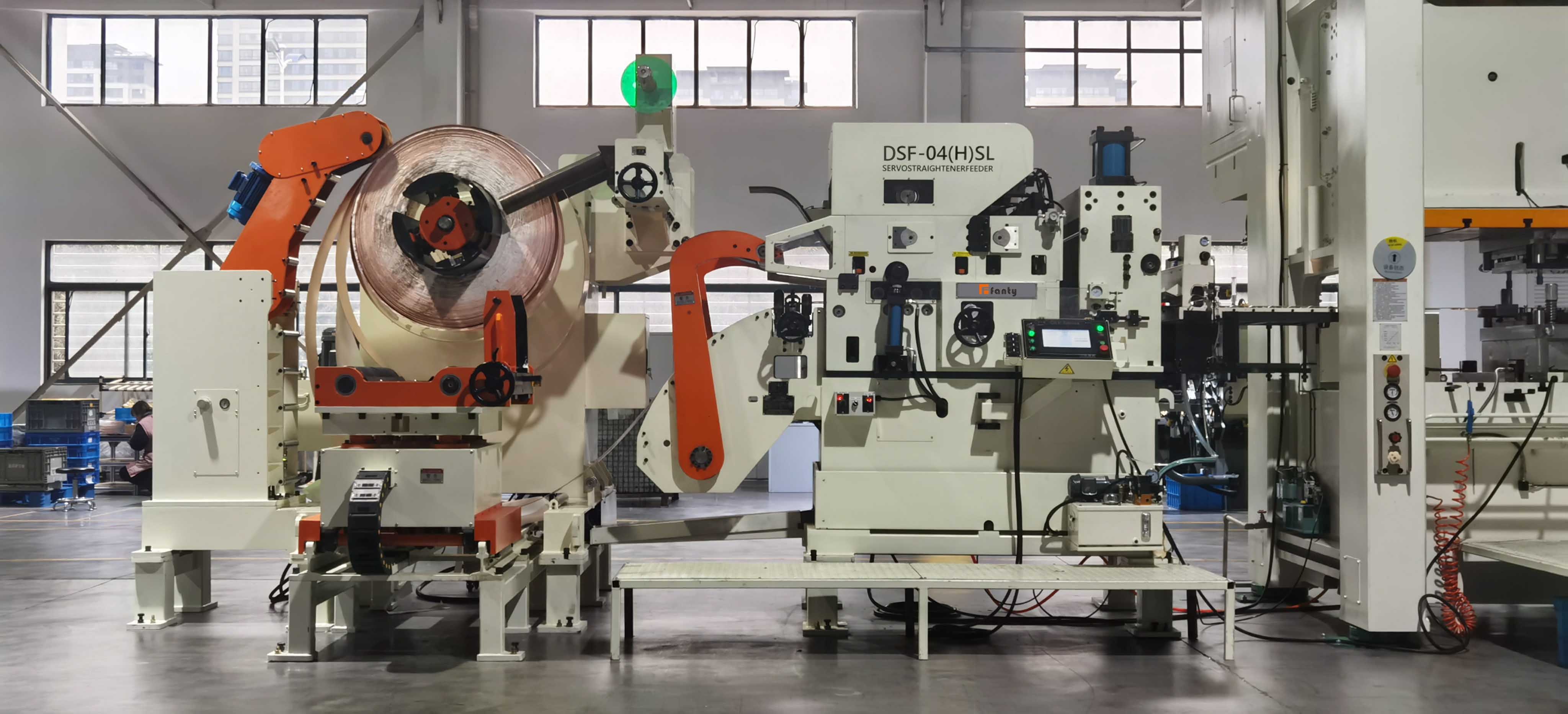

Learn how to maintain and service your coil processing equipment for peak performance. Fanty’s expert tips and support keep your line humming!

Your coil processing equipment is the heartbeat of your factory, and keeping it in top shape is a labor of love. At Fanty, we know how crucial it is to avoid downtime and keep your line humming. With over 10 years of expertise, we’re sharing our best tips to maintain and service your coil handling equipments, ensuring it runs like a dream.

Why Maintenance Matters

Regular maintenance is like giving your equipment a big hug—it extends its life, prevents breakdowns, and keeps your production soaring. Fanty’s 24/7 support is here to help you every step of the way.

Top Maintenance Tips

1. Regular Cleaning

Keep rolls and feeders free of debris to prevent defects. Fanty’s systems are designed for easy cleaning.

2. Lubrication

Proper lubrication reduces wear on moving parts. Follow Fanty’s maintenance guides for best results.

3. Roll Inspections

Check for wear or damage to ensure precision. Fanty’s support team can assist with inspections.

Fanty’s Service Promise

Our 24/7 support and training keep your equipment in top shape. Contact us for a maintenance plan that works for you!

Keep Your Line Humming

With Fanty’s coil processing equipment and support, maintenance is a breeze. Let’s keep your production soaring! Reach out for a free consultation.

About Fanty

Fanty is your global partner in coil processing equipment, delivering innovative solutions like NC Servo Feeders and 3-in-1 systems. With over 10 years of experience, we’re dedicated to your success with reliable machinery and 24/7 support. Visit us at decoilerfeeder.com.

By Fanty’s Passionate Team | Published: July 24, 2025