The Difference Between Galvanized Steel DC53D and DX53D

- Share

- Issue Time

- Aug 13,2025

Summary

Learn the differences between DC53D and DX53D galvanized steel in terms of production process, applications, and how to choose the right coil processing equipment for each.

Understanding the differences between DC53D and DX53D galvanized steel is essential for balancing surface quality, formability, and production efficiency. This guide covers their characteristics, applications, and how to select the right coil processing equipment, with insights from Fanty Machinery.

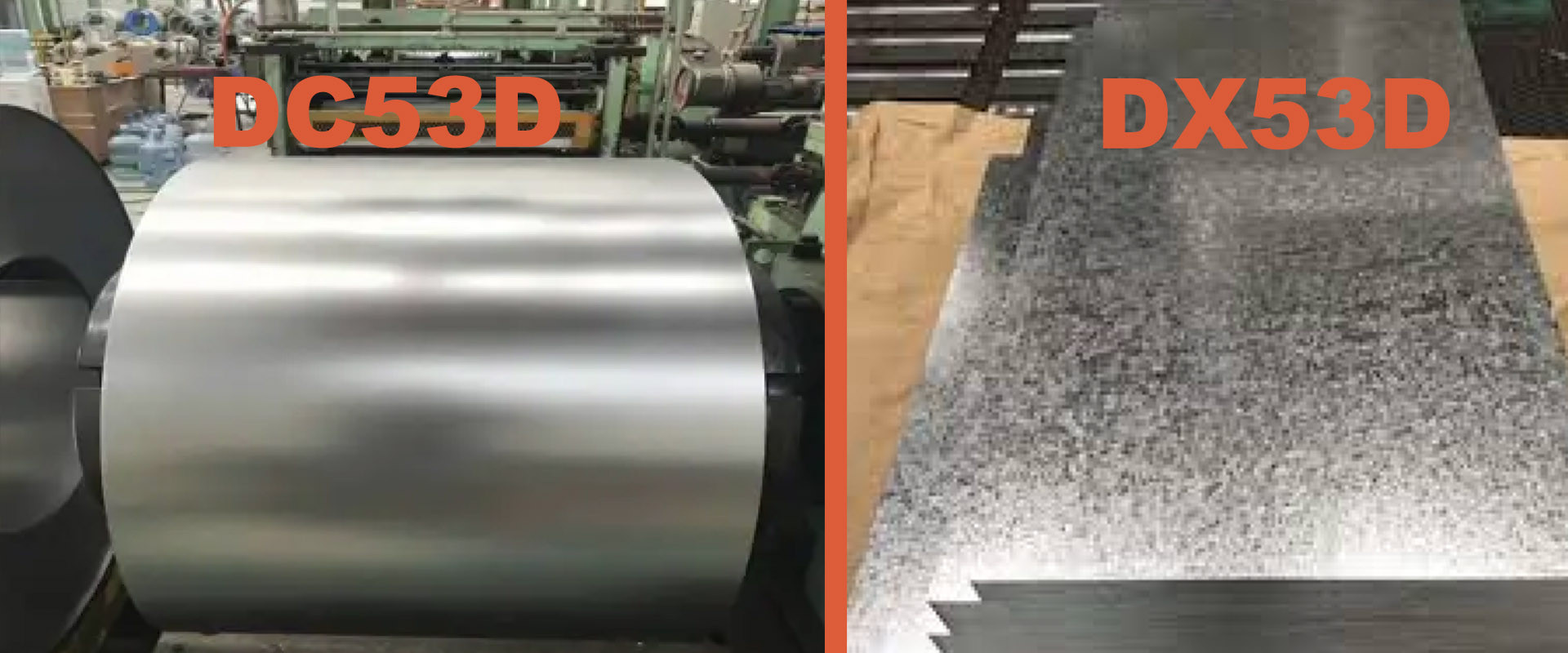

1. Production Process & Surface Finish

DC53D is a cold-rolled galvanized steel sheet with a bright, smooth surface, tight tolerances, and excellent formability—perfect for automotive parts and high-end appliances.

DX53D can be hot-rolled or cold-rolled. Hot-rolled DX53D has a slightly rougher finish and lower dimensional precision, but works well for general forming in construction, appliances, and furniture.

2. Application Differences

- DC53D: Automotive panels, appliance casings, precision parts with strict surface requirements.

- DX53D: Roofing sheets, wall panels, appliance backs, furniture frames.

3. Coil Processing Equipment Selection

3.1 Decoiler

DC53D: Precision decoiler with automatic tension control. DX53D (hot-rolled): Heavy-duty decoiler with high load capacity.

3.2 Straightener / Leveler

DC53D: Precision leveler with multi-roll flattening. DX53D: Standard straightener for general applications.

3.3 Feeder

DC53D: High-accuracy servo feeder. DX53D: Mechanical or servo feeders depending on production needs.

3.4 Protective Handling

Both grades benefit from soft-contact rollers and scratch-prevention systems—especially critical for DC53D's smooth surface.

4. Why Fanty Machinery

Fanty Machinery provides coil processing equipment including decoilers, straighteners, feeders, and integrated coil handling lines. With experience across automotive, appliance, and construction industries, Fanty ensures your equipment is optimized for both DC53D and DX53D. Learn more here.

Conclusion

DC53D and DX53D have distinct rolling methods, surface finishes, and application strengths. The right coil processing equipment—from decoiling to leveling and feeding—ensures optimal performance. Fanty Machinery can deliver tailored solutions for your production line.