What's the Future of Automotive Steels in the Age of Sustainability and High-Tech?

- Share

- Issue Time

- Jun 4,2025

Summary

This article delves into the current state of automotive steels, decoiler straightener feeder for handling these steels, their evolution in automotive manufacturing.

In the fast - paced world of automotive manufacturing, sustainability, lightweighting, and advanced technology are the buzzwords driving innovation. As the industry hurtles towards a future of electric vehicles (EVs), autonomous driving, and enhanced safety features, the role of automotive steels is undergoing a profound transformation. This article delves into the current state of automotive steels, decoiler straightener feeder for handling these steels, their evolution, and what the future holds for this crucial component of the automotive industry.

The Current Landscape of Automotive Steels

Steel has been the backbone of the automotive industry for over a century. Its strength, durability, and relatively low cost make it an ideal material for vehicle construction. However, as environmental concerns and technological advancements reshape the automotive landscape, the demand for high - performance steels with unique properties is on the rise.

Types of Automotive High - Strength Steels

1. Dual Phase Steels (DP Steels)

* Performance Characteristics: DP steels are known for their lack of yield elongation and room - temperature aging. They exhibit a low yield ratio, a high work hardening index, and a high bake hardening value. These properties make them highly suitable for applications where formability and strength are crucial.

Typical Applications:

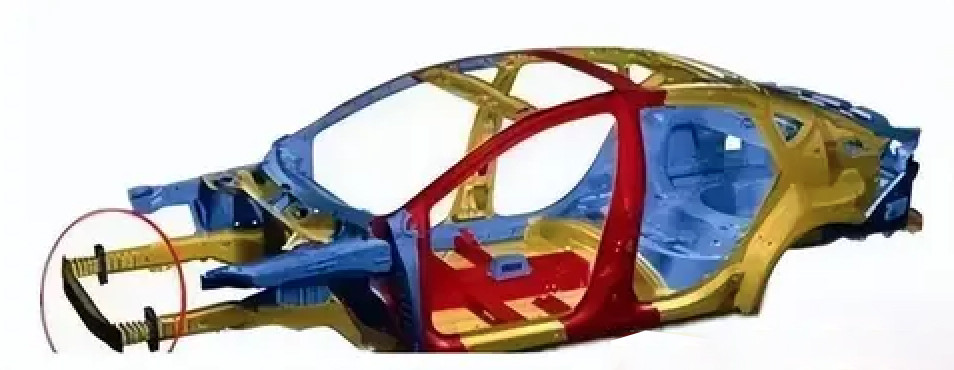

Widely used in structural, reinforcing, and crash components, DP steels are the go - to choice for parts such as vehicle floor cross members, rails, crash bars, and their reinforcing structures.

2. Complex Phase Steels (CP Steels)

* Performance Characteristics: CP steels feature fine grains and relatively high tensile strength. Compared to DP steels of the same strength level, they have significantly higher yield strength. Additionally, they offer good bending performance, high hole expansion performance, high energy absorption capacity, and excellent flanging formability.

Typical Applications:

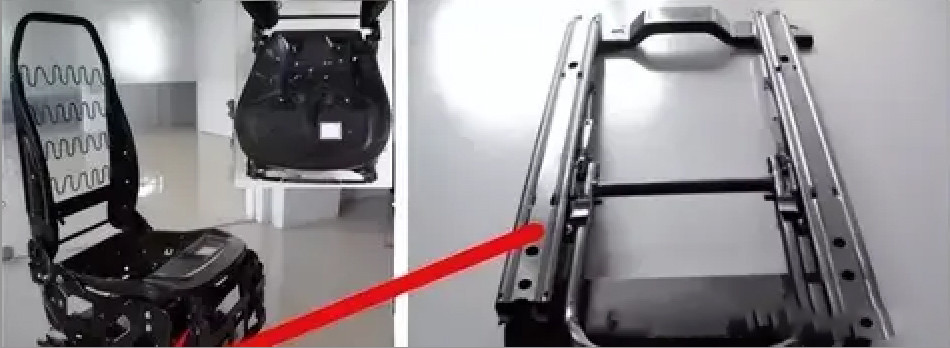

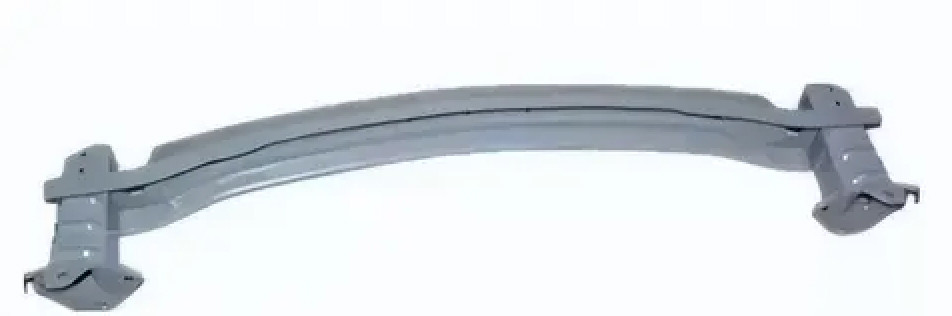

Ideal for chassis suspension parts, B - pillars, bumpers, and seat rails, CP steels play a vital role in ensuring the structural integrity and safety of vehicles.

3.Transformation Induced Plasticity Steels (TRIP Steels)

* Performance Characteristics: TRIP steels contain retained austenite in their microstructure, which gives them excellent formability. During the forming process, the retained austenite transforms into hard martensite, promoting uniform deformation. They also possess high crash absorption energy, a high strength - plasticity product, and a high n - value.

Typical Applications:

Used for complex structural parts like B - pillar reinforcement plates and front longitudinal beams, TRIP steels are essential for meeting the demanding requirements of modern vehicle design.

4.Martensitic Steels (MS Steels)

* Performance Characteristics: MS steels have a high yield ratio and high tensile strength, but their elongation is relatively low. Caution must be exercised due to the risk of delayed cracking. Nevertheless, they offer high crash absorption energy, a high strength - plasticity product, and a high n - value.

Typical Applications:

Suitable for cold stamping of simple parts and roll forming of parts with uniform cross - sections, such as bumpers, sill reinforcement plates, and side door crash bars.

5.Quenching and Partitioning Steels (QP Steels)

* Performance Characteristics: With martensite as the matrix phase, QP steels utilize the TRIP effect of retained austenite during deformation, resulting in a high work hardening capacity. This gives them higher plasticity and formability compared to ultra - high - strength steels of the same level.

* Typical Applications: QP steels are well - suited for complex - shaped automotive safety and structural parts, such as A and B - pillar reinforcement parts.

6.Twinning Induced Plasticity Steels (TWIP Steels)

* Performance Characteristics: TWIP steels are fully austenitic steels with high C, high Mn, and high Al contents. Through the dynamic refinement effect induced by twinning, they achieve extremely high work hardening capacity, boasting ultra - high strength and ultra - high plasticity, with a strength - plasticity product of over 50GPa%.

Typical Applications:

Their excellent formability and ultra - high strength make them ideal for parts with high requirements for material drawing and bulging performance, such as complex - shaped automotive safety and structural parts.

7.Press Hardening/Boron Steels (PH or B Steels)

* Performance Characteristics: PH/B steels have ultra - high strength (tensile strength over 1500MPa), which significantly improves crash performance and enables vehicle body lightweighting. The parts formed from these steels have complex shapes, good formability, and high dimensional accuracy.

Typical Applications:

Used in safety structural parts like front and rear bumpers, A - pillars, B - pillars, and center channels, PH/B steels are crucial for ensuring vehicle safety.

The Evolution of Automotive Steels

The history of automotive steels is intertwined with the development of the automotive industry itself. Since the first automobile was invented in 1885, steel has been a key material in vehicle construction. In the early 20th century, advancements in steel plate/coil production and complex forming technologies led to the replacement of wooden components with steel in automotive structures.

Over the years, the types of steels used in cars have evolved in response to various factors. Initially, low - carbon steel (LC) and interstitial - free steel (IF) were the norm, as they met the strength, formability, cost, and design requirements of the time. However, the 1970s oil crisis spurred the automotive industry to develop high - strength steels to reduce vehicle weight and improve fuel efficiency. This marked the beginning of a new era in automotive steel development, with the continuous increase in the strength levels of automotive steel plates.

Classification of Automotive Steel Plates

1. Traditional High - Strength Steels

Bake hardening steels (BH) are the main type in this category. Their unique mechanical property is that their strength increases during the paint baking process after stamping. The degree of strain hardening during stamping has a significant impact on the strength gain during the subsequent baking process, and different forming methods and strain amounts also influence the bake hardening effect to some extent.

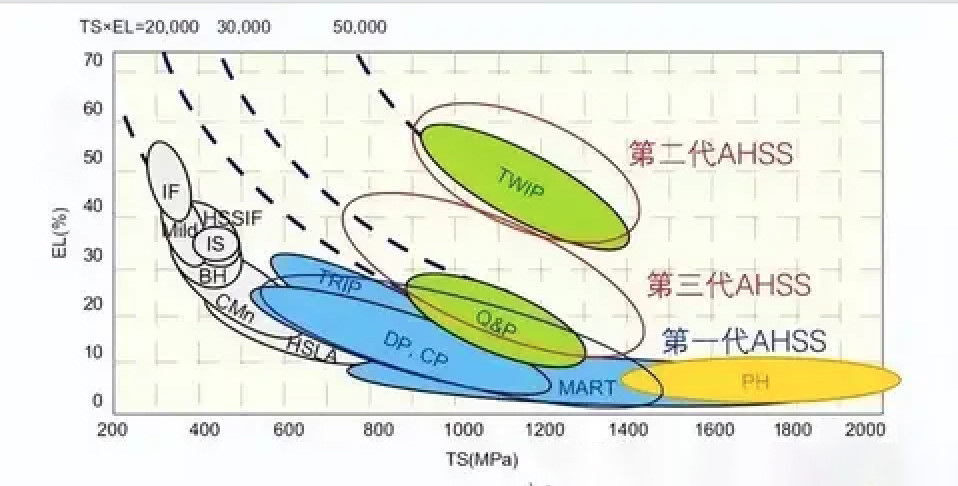

2. Typical First - Generation Advanced High - Strength Steels

Dual phase steels (DP) and transformation induced plasticity steels (TRIP) are the primary representatives. DP steels consist of two phases, either ferrite + bainite or ferrite + martensite. Ferrite, as the soft phase, ensures plasticity and easy forming, while bainite/martensite, as the hard phase, provides reasonable strength.

3. Typical Second - Generation Advanced High - Strength Steels

Twinning induced plasticity steels (TWIP) are the main type in this generation. Based on the formation of mechanical twins due to austenite phase changes during deformation, TWIP steels can absorb crash energy. Their basic composition is 18%Mn - 3%Si - 3%Al, and the composition can be adjusted according to the performance requirements of components and production bottlenecks.

4. Third - Generation Advanced High - Strength Steels

To bridge the gap between the first and second generations of high - strength steels, varieties with excellent combinations of high strength and high plasticity, such as Quenching and Partitioning (Q&P) steels, have been developed. Their room - temperature microstructure consists of ferrite, martensite, and austenite. The design principle involves forming a significant amount of martensite after quenching to a certain temperature, followed by secondary heating to allow carbon atoms in martensite to diffuse into the retained austenite, enhancing its stability. The strength - plasticity product of Q&P steels far exceeds that of the first and second generations of advanced high - strength steels.

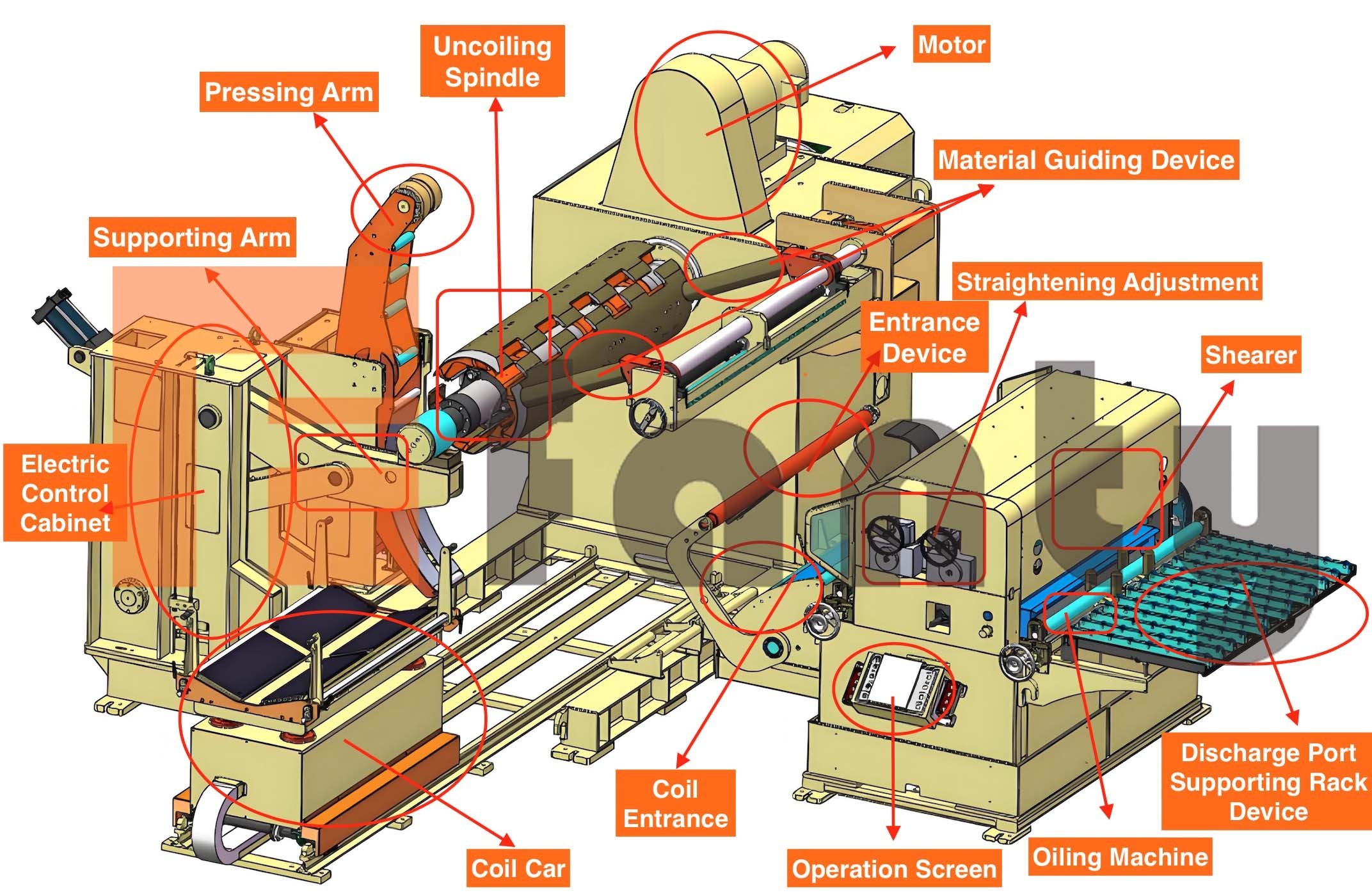

The Machine to Handle These Automotive Steels

Decoiler Straightener Feeder

A Decoiler Straightener Feeder machine is an equipment designed to process coil materials in the metal stamping production. It combines three essential functions – decoiling, straightening, and feeding – into a single unit, effectively eliminating manual handling, reducing setup time, and enhancing overall production efficiency, and save labor cost for sure.

the FANTY decoiler straightener feeder is made to accommodate a wide variety of material width and thickness.

Development Trends and Research Hotspots of Automotive Steels

1. Lightweighting for Sustainability

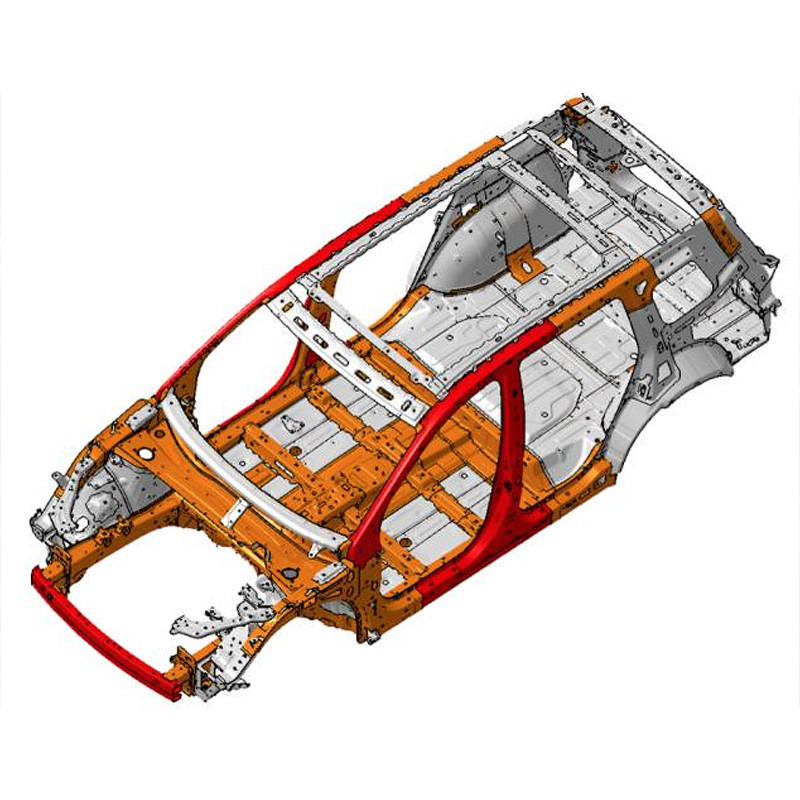

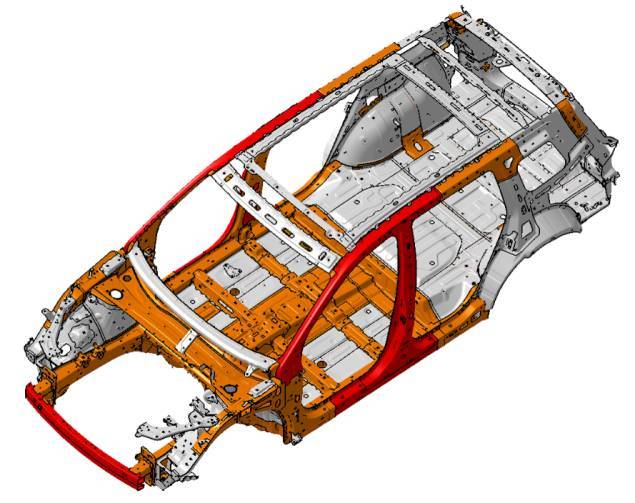

In Europe and the United States, the use of high - strength steels in vehicle body structures, ranging from 600MPa/40% to 1600MPa/20%, has enabled a weight reduction of at least 5 - 8%. This not only contributes to better fuel efficiency in traditional vehicles but also extends the range of electric vehicles. As the automotive industry moves towards more sustainable transportation, lightweighting through the use of advanced high - strength steels will continue to be a key trend.

2. Meeting the Demands of Electric Vehicles

The rapid growth of the electric vehicle market presents both opportunities and challenges for automotive steel manufacturers. EVs require steels with specific properties, such as high strength for battery enclosures to ensure safety and lightweight materials to improve energy efficiency. Manufacturers are researching and developing new steel grades tailored to the unique requirements of EVs, including those for motor components and battery casings.

3. Research in Advanced Microstructures and Properties

International organizations and research institutions are focusing on areas such as the study of advanced high - strength steel microstructures and mechanical properties, carbon diffusion processes, particle size and interface effects, and the development of new types of steels like nano - acicular ferrite - based dual - phase steels and high - strength and high - plasticity bainitic steels. Understanding these aspects is crucial for developing steels with improved performance.

4. Formability and Modeling

Research is also being conducted on the formability and springback behavior of advanced high - strength steels, as well as the development of corresponding models. Accurate modeling can help automotive manufacturers optimize the design and manufacturing processes, reducing costs and improving the quality of steel - based automotive components.

Conclusion

In Europe and the United States, the use of high - strength steels in vehicle body structures, ranging from 600MPa/40% to 1600MPa/20%, has enabled a weight reduction of at least 5 - 8%. This not only contributes to better fuel efficiency in traditional vehicles but also extends the range of electric vehicles. As the automotive industry moves towards more sustainable transportation, lightweighting through the use of advanced high - strength steels will continue to be a key trend.