What Are the Benefits of a Double Head Uncoiler for Continuous Production?

- Share

- Issue Time

- Sep 17,2025

Summary

Explore the benefits of a Double Head Uncoiler (Double Head Decoiler) for seamless continuous production. Learn how it reduces downtime and boosts efficiency with Fanty’s expert solutions.

By Fanty Experts | Published: September 17, 2025

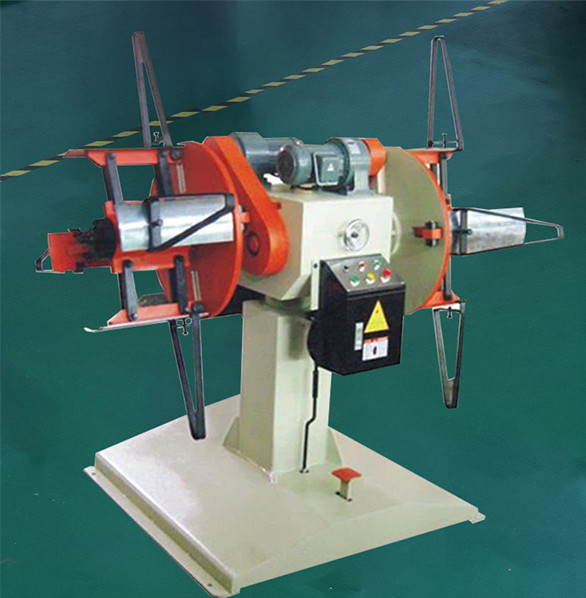

A Double Head Uncoiler, also known as a Double Head Decoiler, is transforming continuous production in metal coil processing by enabling non-stop operations. As industries like automotive, HVAC, and construction demand higher efficiency, this coil processing equipment minimizes interruptions and maximizes output. This guide explores its key benefits, drawing insights from industry leaders. At Fanty, with over 13 years of expertise since our founding in 2013, we specialize in custom Double Head Uncoilers designed to streamline your production lines and reduce downtime.

What is a Double Head Uncoiler?

A Double Head Uncoiler features two mandrels for holding metal coils (e.g., steel, aluminum, AHSS), allowing one to unwind while the other is loaded. This design supports continuous feeding in stamping, roll forming, and tube mill lines. Unlike single-head models, it eliminates coil change pauses, making it ideal for high-volume manufacturing. Fanty’s Double Head Decoilers, built with durable welded steel and hydraulic expansion, ensure precise unwinding with radial runout under 0.01mm.

Key Benefits of a Double Head Uncoiler for Continuous Production

Here are the primary advantages:

- Reduced Downtime: Alternate heads allow coil changes without stopping production, saving 20-30% in tim.

- Increased Efficiency: Continuous unwinding boosts throughput by 25-40%, ideal for high-speed lines.

- Improved Safety: Automated loading with pressing arms minimizes manual handling risks.

- Precision and Alignment: Dual heads ensure even material feeding, reducing defects in stamping or slitting.

- Cost Savings: Lower labor needs and waste from interruptions lead to better ROI.

- Versatility: Handles various coil sizes (3-10 tons, widths up to 2000mm).

Fanty’s Double Head Uncoilers integrate these benefits with optional coil cars and PLC controls, supporting Industry 4.0 for real-time monitoring.

Applications in Continuous Production

They maintain steady material flow for automotive parts or construction beams.

Fanty: Innovating Double Head Uncoiler Solutions

Since 2013, Fanty has led in metal stamping automation from our 45,000㎡ Dongguan facility, with 370 staff including 80 R&D experts. Our CE-certified equipment, using world-brand components, achieves HRC60 ±2 hardness for rollers. We’ve delivered custom unwinding lines globally since 2018, focusing on minimizing downtime.

Case Study: A tube mill client adopted Fanty’s Double Head Uncoiler in 2022, achieving 30% higher continuous output with zero interruptions.

Frequently Asked Questions

How does a Double Head Uncoiler reduce downtime?

By allowing one head to load while the other unwinds, ensuring non-stop production; Fanty’s models optimize this with quick switches.

Is a Double Head Decoiler suitable for small factories?

Yes, for medium to high-volume; Fanty provides compact, customizable options.

What coil sizes can it handle?

Up to 10 tons and 2000mm widths; Fanty tailors for specific materials like AHSS.

Conclusion

The benefits of a Double Head Uncoiler—reduced downtime, enhanced efficiency, and safety—make it essential for continuous production. Fanty’s custom solutions, backed by a decade of innovation, help you achieve these gains. Contact us for tailored advice.

About Fanty

Fanty, founded in 2013 in Dongguan, Guangdong, is a global leader in metal stamping automation with a 45,000㎡ facility and 370 staff, including 80 R&D experts. We produce decoilers, feeders, and 3-in-1 systems, providing CE-certified custom solutions to minimize downtime and boost efficiency. Visit decoilerfeeder.com for more.