What is Coil Processing Equipment? Your Friendly Guide for 2025

- Share

- Issue Time

- Jul 14,2025

Summary

Learn about coil processing equipment, its types, applications, and benefits for metal manufacturing.

Imagine turning massive metal coils into perfectly shaped parts for cars, HVAC systems, or even skyscrapers. We’re thrilled to share this guide, diving into the types, uses, and game-changing benefits of these coil processing machines. At Fanty, we’ve spent over 10 years crafting innovative solutions to help manufacturers like you bring your vision to life with ease and precision.

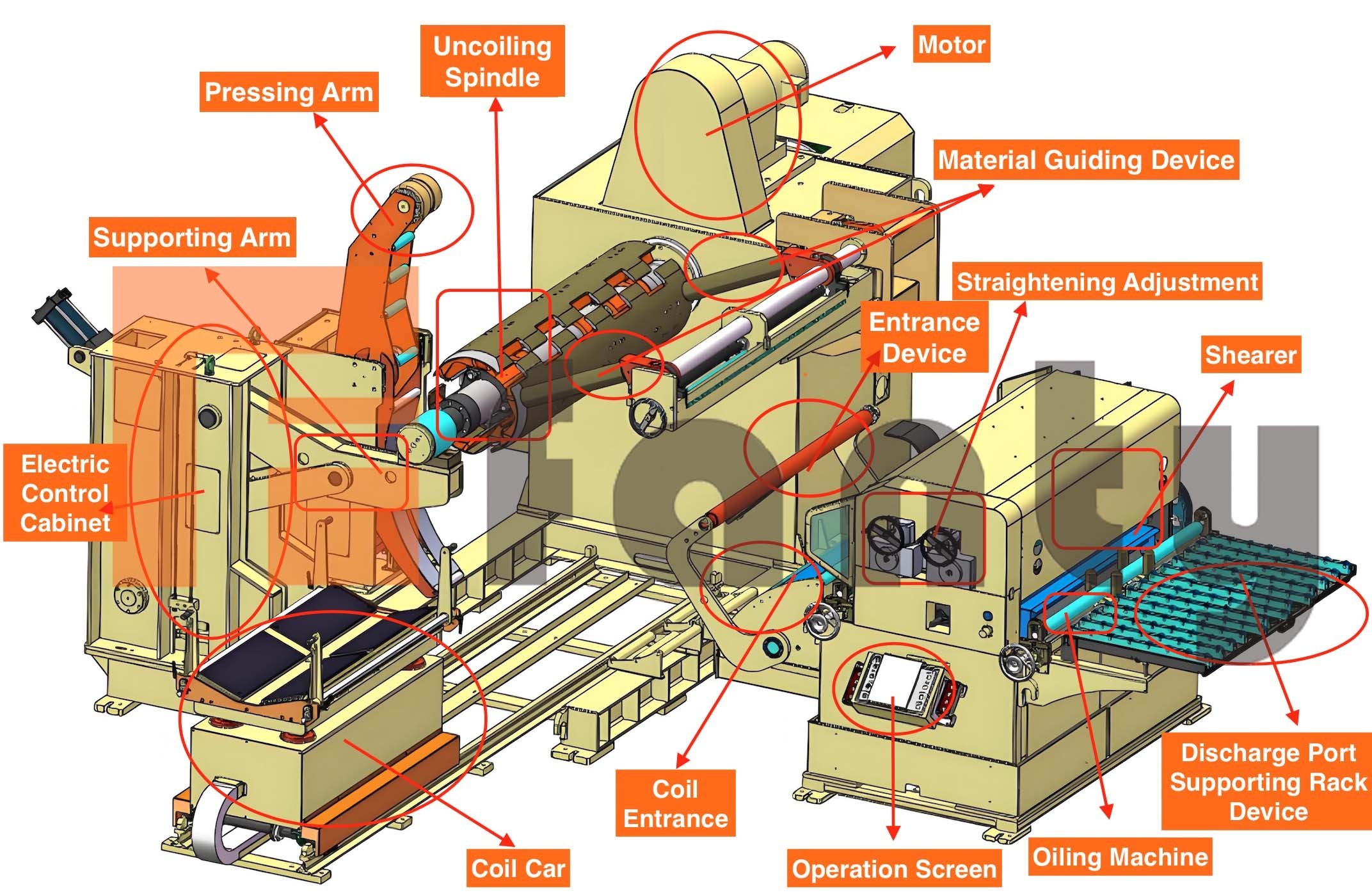

So, What Exactly is Coil Processing Equipment?

At its heart, coil processing equipment takes giant rolls of metal—think steel, aluminum, or advanced high-strength steel (AHSS)—and transforms them into ready-to-use forms for manufacturing. Unlike working with flat sheets, coils are like the super-efficient cousin, saving you time, money, and material. From unwinding to straightening to cutting, these machines handle it all with jaw-dropping precision.

We at Fanty are passionate about making this process seamless. Our NC Servo Feeders and 3-in-1 Straightener-Feeder-Decoilers are designed to make your production line hum with efficiency, no matter where you are in the world.

Why You’ll Love Coil Processing

- Supercharged Efficiency: Say goodbye to downtime! Coil processing cuts material handling, boosting your output by up to 30%.

- Save Big on Waste: Smart cutting and nesting slash scrap by 20–30%, keeping more money in your pocket.

- Top-Notch Precision: Create flawless parts for cars or planes with equipment that nails flatness and accuracy every time.

The Amazing Types of Coil Processing Equipment

Think of coil processing equipment as a superhero team, each member with a unique power. Let’s meet the stars, backed by Fanty’s expertise in crafting top-tier machinery.

1. Uncoilers/Decoilers

These champs kick things off by unwinding metal coils smoothly. They handle all sorts of coils, from lightweight aluminum to tough AHSS. Fanty’s uncoilers, with auto-centering and tension control, make the process feel like a breeze.

2. Straighteners

Got pesky coil bends? Straighteners smooth out stresses like coil set and crossbow, delivering perfectly flat material. Fanty’s Fineblanking Edition straighteners are a game-changer for precision tasks like automotive stamping.

3. Levelers

Levelers are the perfectionists, ironing out surface flaws and stresses, especially for AHSS. Fanty’s leveling systems adapt on the fly to different material thicknesses, ensuring top-quality results.

4. Slitting Lines

Need narrow strips for HVAC or appliances? Slitting lines slice wide coils with pinpoint accuracy. Fanty’s slitting lines, with quick tooling changes and smart controls, make it effortless.

5. Cut-to-Length (CTL) Lines

CTL lines turn coils into precise sheets, often stacking them automatically for maximum efficiency. Fanty’s CTL systems, with advanced servo feeds, deliver consistent cuts you can count on.

6. Servo Feeds

Servo feeds are the precision wizards, moving material with exact control using servo motors. Fanty’s NC Servo Feeders shine in high-speed stamping and complex patterns, making production a joy.

Where Coil Processing Equipment Shines

These machines are the unsung heroes behind countless industries, turning raw coils into parts that power our world:

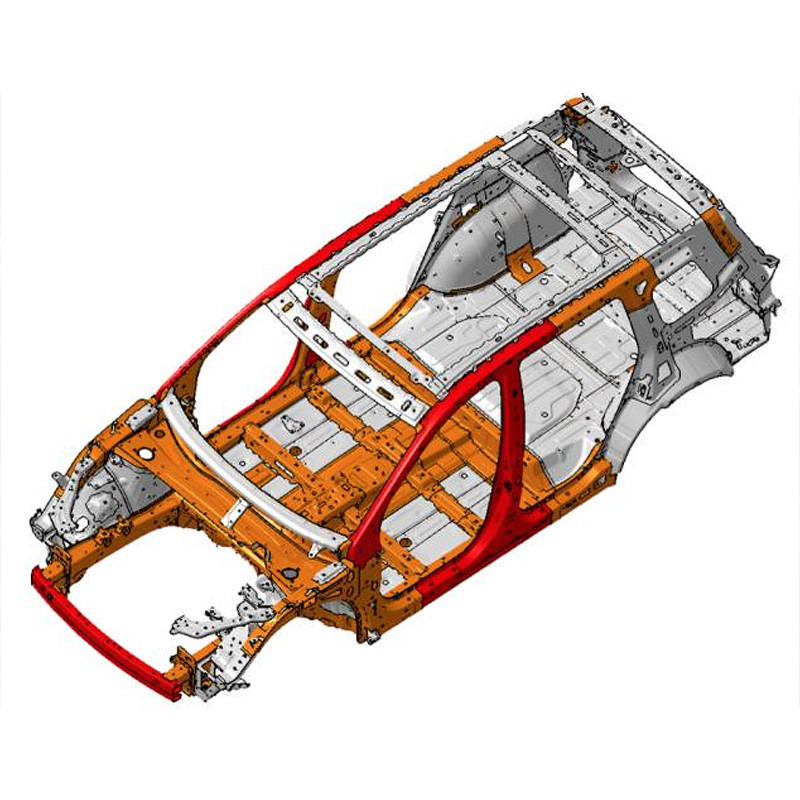

- Automotive: Crafting sleek body panels and sturdy chassis from AHSS.

- HVAC: Building precise ducting and fittings with ease.

- Construction: Creating strong beams and roofing materials.

- Appliances: Shaping panels for fridges, washers, and more.

- Aerospace: Producing lightweight, high-strength aircraft components.

Fanty’s equipment is loved worldwide, with custom solutions for every industry. Our 3-in-1 systems, for example, have slashed automotive stamping setup times by 25%, making production smoother than ever.

Why You’ll Be Thrilled with Coil Processing Equipment

Investing in these machines is like giving your production line a superpower. Here’s why they’re a game-changer:

- Boost Productivity: Fanty’s automated systems cut manual work, skyrocketing output by 20–40%.

- Save on Materials: Precision cutting and nesting keep waste low, saving you big bucks.

- Stunning Quality: Advanced leveling ensures flawless parts, perfect for demanding AHSS projects.

- Flexibility Galore: Modular designs let you switch materials and thicknesses with ease.

- Safe and Sound: Features like auto coil loading keep your team safe and worry-free.

Fanty’s PLC-controlled systems bring Industry 4.0 to life, with real-time monitoring that makes your operations smarter and smoother.

How to Pick the Perfect Coil Processing Equipment

Choosing the right equipment can feel overwhelming, but we’re here to help you find the perfect fit:

- Material Type: Whether it’s steel, aluminum, or AHSS, you’ll need the right roll setups.

- Coil Specs: Width, thickness, and weight guide your equipment choice.

- Your Goals: High-speed lines for big operations or Fanty’s compact 3-in-1 for smaller spaces.

- Automation: HMI and IoT features make your line smarter and more efficient.

- Budget: Balance costs with long-term savings from less waste and downtime.

Fanty’s got your back with free consultations to find equipment that feels just right. With over 20 years of know-how, we’ll help you maximize your investment. Reach out for a personalized plan!

Fanty: Your Trusted Partner in Coil Processing

At Fanty, we’re more than just a company—we’re your partner in success. For over 20 years, we’ve crafted innovative solutions like NC Servo Feeders, 3-in-1 systems, and precision levelers that manufacturers worldwide adore. Our 24/7 support and hands-on training keep your operations running smoothly.

Real Success Story: An automotive stamper teamed up with Fanty to revamp their coil processing line. Our 3-in-1 Straightener-Feeder-Decoiler cut setup times by 25% and boosted part quality, saving 15% on material costs. Check out more success stories.

Your Burning Questions, Answered

What materials can coil processing equipment handle?

From steel to aluminum to tough AHSS, these machines handle it all. Fanty’s versatile systems work with materials from 0.03” to 0.25” thick, making your production dreams a reality.

How does coil processing save on waste?

With clever cutting, nesting, and automation, you’ll cut scrap by 20–30%, saving you serious cash compared to sheet processing.

What’s the difference between slitting and cut-to-length lines?

Slitting lines create narrow strips, perfect for HVAC or appliances, while cut-to-length lines make flat sheets. Fanty’s automated systems for both deliver spot-on accuracy.

Let’s Transform Your Manufacturing

Coil processing equipment is your ticket to faster, smarter, and more cost-effective manufacturing. From uncoilers to servo feeds, these machines bring precision and savings to industries worldwide. With Fanty’s innovative solutions and decades of expertise, we’re excited to help you take your production to the next level. Ready to get started? Contact Fanty sales@sz-fanty.com for a free consultation or grab our free guide to choosing the perfect equipment!

About Fanty

Fanty is your global partner in coil processing equipment, delivering innovative solutions like NC Servo Feeders, 3-in-1 systems, and precision leveling equipment. With over 10 years of experience, we’re dedicated to providing reliable, custom machinery and 24/7 support to manufacturers everywhere. Visit us at decoilerfeeder.com to see how we can spark your production success.

By Fanty’s Passionate Team | Published: July 14, 2025