What is a Decoiler Machine and How Does it Streamline Metal Processing?

- Share

- Issue Time

- Sep 5,2025

Summary

Decoiler machines are indispensable in modern metalworking, serving as the foundational equipment for unwinding large metal coils into flat sheets or strips for further processing.

In the intricate world of metal fabrication and manufacturing, efficiency and precision are paramount. At the very beginning of many coil feeding lines, where raw coiled materials transform into finished products, lies an unassuming yet critical piece of equipment: the Decoiler. Often overlooked, it plays a pivotal role in ensuring a smooth and continuous flow of material for subsequent coil processes.

What Exactly Is a Decoiler?

A decoiler, also frequently referred to as an uncoiler, is a specialized machine designed to unwind and flatten large coils of metal materials, such as steel, aluminum, or even plastic film and paper, into continuous sheets or strips. Its primary function is to prepare the coiled material for downstream machinery, like presses, straighteners, or roll formers, by providing a steady and controlled feed. Without a decoiler, manually handling these heavy and tightly wound coils would be incredibly inefficient, unsafe, and prone to material damage or deformation.

Beyond the Basics: Why Decoiling is Crucial

The significance of a decoiler extends far beyond simply unwinding a coil. It is the crucial first step in any coil-based production line, directly impacting overall stability, production efficiency, material utilization, and the quality of the final product. By automating the material feeding process, decoilers eliminate the need for laborious manual unwinding, significantly reducing labor costs and minimizing downtime associated with coil changeovers.

Anatomy of a Decoiler: Key Components Explored

While seemingly straightforward, a decoiler is composed of several well-integrated parts that work in harmony to ensure efficient and reliable operation. Understanding these components provides insight into how the machine achieves its precision and control:

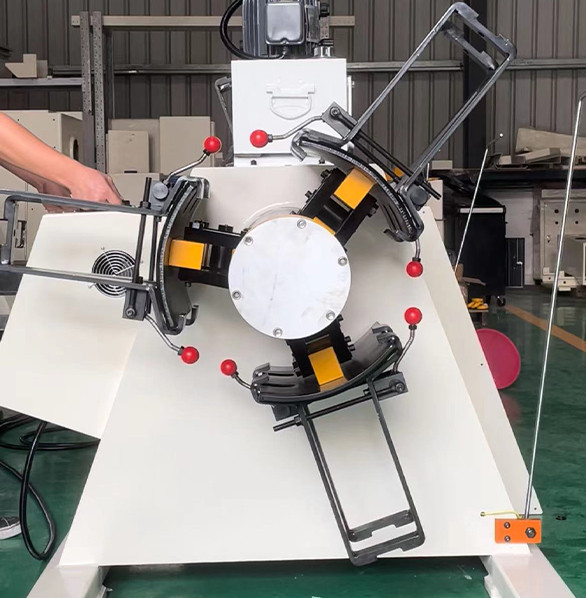

- Mandrel or Coil Holder: This is the central cylindrical shaft that securely holds the coiled material in place. It often expands mechanically or hydraulically to grip the inner diameter of the coil, ensuring stability and preventing slippage during unwinding.

- Unwinding Rolls / Tension Control System: These components regulate the release and tension of the material as it unwinds. Tension sensors and feedback devices maintain a consistent tension level, preventing distortion, breakage, or excessive slack.

- Motor and Gearbox: Powered decoilers utilize a motor and gearbox to drive the rotation of the mandrel, facilitating controlled and gradual material release. Some models feature variable frequency drives for precise speed adjustment.

- Braking System: A brake is applied to control material tension and prevent uncontrolled unwinding, ensuring material integrity.

- Coil Support System (e.g., Coil Car, Hold-down Arms): These systems assist in loading coils onto the mandrel and maintaining their alignment and support throughout the unwinding process.

- Loop Control System: Advanced decoilers may incorporate a loop control system, often using photocells or ultrasonic sensors, to manage the material loop between the decoiler and downstream equipment, preventing buckling or slack.

The Decoiling Process: How Does It Work Step-by-Step?

The working principle of a decoiler machine is surprisingly elegant, ensuring a seamless material flow. Here's a typical step-by-step breakdown:

- Coil Loading: The coiled material is first loaded onto the decoiler's mandrel. This can be done manually for smaller coils or with the aid of a coil car or crane for larger, heavier coils.

- Expansion and Centering: The mandrel expands, often hydraulically, to clamp the coil core securely. This ensures the coil is centered and held firmly for stable rotation.

- Initiating Uncoiling: The decoiler's motor begins to rotate the mandrel, gradually releasing the material from the coil.

- Tension Control: As the material unwinds, a tension control system continuously monitors and adjusts resistance, ensuring the material remains consistently taut but not overstressed. This prevents issues like material rebound, slack, or wrinkling.

- Feeding Downstream Equipment: Once unwound, the flat material is then fed into the next stage of the production line—be it a straightener for flatness correction, a feeder for precise positioning, or directly into a stamping press or roll former.

This continuous, controlled unwinding process is vital for high-speed, automated production lines.

Types of Decoiling Machines: Finding the Right Fit

Decoilers come in various configurations, each suited for different coil specifications, production volumes, and levels of automation. The choice depends on factors like coil weight, width, material type, and required production speed. Some common types include:

- Manual Decoiler Machines: Simplest type, relying on manual labor for unwinding, suitable for small to medium-sized coils and low-volume production.

- Motorized Decoiler Machines: Use an electric motor to unwind the coil, offering greater efficiency and speed. They can be single-motor or dual-motor, with dual-motor systems providing better tension control for heavier coils.

- Hydraulic Decoiler Machines: Utilize hydraulic systems for enhanced power, precision, and control, especially for large and heavy coils. They offer precise tension control and stability.

- Compact Decoiler: Often integrate the decoiler with a straightener and feeder into a single unit, saving space.

- Heavy-Duty Decoiler: Designed to handle exceptionally large and heavy coils, typically found in high-volume industrial settings.

- Powered vs. Non-Powered Decoiler: Powered machines actively drive the unwinding (with a motor), while non-powered ones rely on the pulling force from downstream equipment.

- Double Mandrel Decoiler: Features two mandrels, allowing for faster coil changeover as one coil can be prepared while another is being unwound, thus improving efficiency.

Where Are Decoiler Machines Used? Key Applications

Decoilers are integral across a wide array of industries that process coiled materials. Their versatility makes them indispensable for:

- Metal Fabrication: General cutting, stamping, and forming operations.

- Automotive Industry: Production of car body parts, chassis components, and exhaust systems.

- Construction: Unwinding steel or aluminum sheets for roofing, cladding, and structural elements.

- HVAC Manufacturing: Fabricating air ducts and ventilation systems.

- Appliance and Electronics Manufacturing: Producing housings and internal components for white goods and consumer electronics.

- Roll Forming Lines: Feeding material for the continuous shaping of metal profiles.

- Laser Cutting and Shearing Lines: Providing flat, consistent material for precision cutting.

The Advantages of Integrating a Decoiler in Your Production Line

The strategic integration of a decoiler machine yields numerous operational and economic benefits:

| Advantage | Description |

|---|---|

| Enhanced Efficiency | Automates material feed, reducing manual labor and streamlining the production process, leading to continuous operation and higher output. |

| Improved Material Usage | Consistent tension control and precise unwinding minimize material waste from snags, kinks, or deformation. |

| Reduced Labor Costs | Automating the unwinding process significantly cuts down on labor required for coil handling and changeovers. |

| Increased Safety | Mechanized handling of heavy coils reduces the risk of operator injuries associated with manual lifting and unwinding. |

| Consistent Material Quality | Ensures material is flat and fed smoothly, preventing defects and maintaining product quality for subsequent processes. |

| Reduced Downtime | Faster coil changes and reliable material supply minimize interruptions in the production line. |

Decoiler vs. Uncoiler: Is There a Difference?

The terms "decoiler" and "uncoiler" are often used interchangeably in the industry to describe the same machine that unwinds coils. However, some distinction exists where "decoiler" might be preferred for more automated, precision-oriented applications found in advanced metal stamping or high-volume lines, while "uncoiler" could refer to simpler or manually operated coil holders. Ultimately, for most practical purposes, they refer to the same equipment performing the same function.

Maximizing Efficiency: Tips for Decoiler Operation and Maintenance

To ensure your decoiler machine operates at peak performance and has a long lifespan, proper operation and routine maintenance are essential:

- Regular Lubrication: Adhere to manufacturer recommendations for lubricating moving parts and bearings to reduce friction and wear.

- Cleaning: Keep the machine clean from debris, dust, and metal shavings that can accumulate and affect performance.

- Inspection: Regularly inspect components like the mandrel, unwinding rolls, and sensors for wear, damage, or misalignment.

- Tension System Calibration: Periodically calibrate the tension control system to ensure consistent and accurate material feeding.

- Safety Checks: Always verify that safety features such as emergency stops and guards are fully functional before operation.

Selecting the Right Decoiler for Your Needs

Choosing the appropriate decoiler involves careful consideration of several factors:

- Coil Specifications: Determine the maximum weight, width, and outer/inner diameter of the coils you'll be processing.

- Material Type: Consider the thickness and type of material (e.g., steel, aluminum, exotic alloys) as this can influence the required power and precision.

- Automation Level: Decide whether manual, motorized, hydraulic, or fully automatic operation fits your production volume and budget.

- Integration with Existing Equipment: Ensure compatibility with your current straighteners, feeders, and presses.

- Space Limitations: Assess the available floor space, especially for compact or combined units.

- Safety Features: Prioritize machines with robust safety mechanisms to protect operators.

The Future of Decoiling Technology

As manufacturing trends embrace greater automation and precision, decoiler technology continues to evolve. Future advancements will likely focus on even more sophisticated sensor integration, AI-driven predictive maintenance, and further improvements in energy efficiency. Fully automatic decoilers, capable of continuous operation with minimal human intervention, represent the pinnacle of current R&D, promising enhanced productivity and even finer control over material processing.

Conclusion

As the starting point of any coil-based production line, the decoiler is a crucial piece of equipment that ensures production rhythm, material efficiency, and seamless process flow. By efficiently unwinding heavy coiled materials, decoiler machines underpin the reliability and productivity of modern manufacturing processes. Their role in optimizing material handling, enhancing safety, and fostering consistent product quality makes them an indispensable asset. Investing in the right decoiler and maintaining it diligently is a commitment to operational excellence and a competitive edge in today's demanding industrial landscape.