What is a Decoiler for Steel Strip?

- Share

- Issue Time

- Sep 30,2025

Summary

Wondering what a decoiler for steel strip is? This guide covers types, benefits, and applications in metal processing, plus how Fanty's uncoilers enhance efficiency and precision.

If you've ever dealt with metal fabrication, you know handling steel strips can be a real pain without the right tools. That's where a decoiler for steel strip—basically an uncoiler designed for narrower steel coils—comes in handy. It unwinds those coiled strips smoothly, feeding them into presses or cutters without tangles or waste. I've chatted with plenty of shop owners who swear by these machines for keeping lines running efficiently. At Fanty , we've been crafting these since 2013, specializing in metal stamping automation to solve real-world headaches. With our 370-strong team, including 80+ R&D experts, and a 45,000㎡ Dongguan facility packed with 8 assembly workshops, we've hit milestones like our first U.S. custom line in 2018 and mass-producing smart gear in 2017. In this guide, we'll unpack what these decoilers are, their types, key parts, and why they're a must for 2025 ops—drawing from top industry practices like those from HZ Roll Forming and StanGroup. Let's get into it.

Understanding the Role of a Decoiler for Steel Strip

Simply put, a decoiler for steel strip holds and pays off coiled steel—often narrower widths used in stamping or forming—into a straight feed for processing. It prevents the strip from springing back or kinking, which is a common issue with manual handling. In industries like automotive or appliances, where precision matters, these machines ensure consistent tension and speed, reducing defects. The key is controlled unwinding to match production pace. At Fanty, our decoilers tackle this head-on, with features like auto-tension that've helped clients cut waste by 15% since our overseas push in 2014.

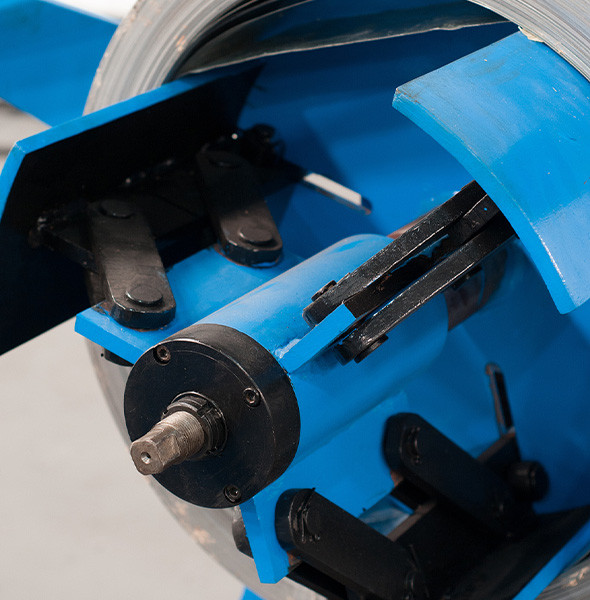

Core Components That Make It Work

These aren't just basic reels—they're built with smart parts for reliability. Based on designs from top makers like StanGroup and HZ Roll Forming, here's what you'll find:

- Mandrel: The expanding core that grips the coil's inner diameter—Fanty's hydraulic versions adjust for 20-24" IDs with under 0.01mm runout for flawless feeds.

- Braking and Tension System: Keeps the strip taut; our frequency converters allow speeds up to 500 FPM, ideal for steel strips in high-volume lines.

- Supports and Arms: Stabilize coils up to 20 tons—think A-frames and pressing arms to prevent slippage, a feature we refined during our 2020-2022 online support era.

- Drive and Controls: Motors or hydraulics with PLC interfaces; Fanty's integrate sensors for auto-syncing with feeders or presses.

Our ISO-certified builds (HRC60 ± 2 hardness) ensure these hold up, just like the durable options from ALEKVS or Alibaba suppliers.

\

Types of Decoilers for Steel Strip: Which Fits Your Needs?

Options vary by scale, much like the custom capacities (2.5-15 tons) from HZ Roll Forming or StanGroup's manual models. Here's a quick rundown:

- Manual Decoilers: Hand-operated for light strips under 5 tons—great for small runs or construction, like ALEKVS' sheet metal versions; Fanty's compact ones are easy to move.

- Motorized Uncoilers: Electric with reducers for reliable function; our dual-motor series handles medium-duty strips with belt drives for low faults.

- Hydraulic Decoilers: Powerhouses for heavier steel strips (10-20 tons); Fanty's reduce setup by 50%, echoing Technic Machines' precision feeding.

- Specialized Variants: Like MT-400 for 400mm strips from Made-in-China or coil-loading cars for efficiency; we offer OEM/ODM for custom fits, including robotic integrations from our 2015 expansion.

For 2025's automation push, our IoT-equipped models stand out, building on our 2017 mass production milestone.

| Type | Capacity | Best For | Fanty Highlight |

|---|---|---|---|

| Manual | Up to 5 tons | Small shops | Portable and affordable |

| Motorized | 5-10 tons | Medium production | Reliable belt drives |

| Hydraulic | 10-20 tons | Heavy stamping | 50% faster setup |

| Specialized | Varies | Custom lines | OEM/ODM with IoT |

Benefits and Real-World Applications

A good decoiler boosts output by 20-30%, cuts scrap, and amps up safety—like in SteelDrumProduction's feeding systems or Alibaba's durable uncoilers. Applications span automotive chassis, construction beams, and appliance parts. Fanty's solutions, with after-sales training and parts, have delivered these gains globally, from our resilient 2020-2022 support to custom U.S. lines.

Final Thoughts: Elevate Your Line with the Right Decoiler

A decoiler for steel strip is your ticket to smoother, faster metal work—don't skimp on quality. With Fanty's innovation-driven approach, customer focus, and global expertise, we're here to tailor uncoilers that minimize downtime and maximize efficiency. Check out our range or drop a line for custom advice.

Fanty: Revolutionizing Metal Stamping Automation Since 2013. Your Trusted Global Partner.

Authored by Fanty's engineering team, blending over a decade of hands-on experience with the latest industry trends. For quotes or demos, email sales at decoilerfeeder.com.