How to choose punch automation equipment for stamping terminal connectors?

- Share

- Issue Time

- Apr 15,2020

Summary

Terminal connectors are usually processed by high-speed punch presses, and high-speed punch press stamping processes.

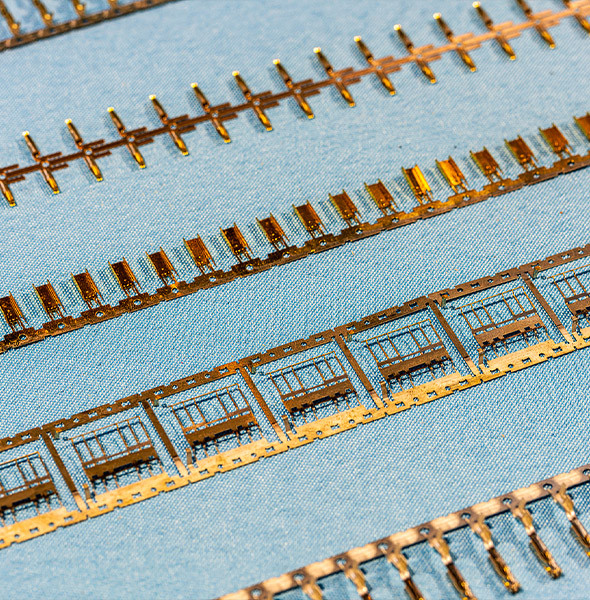

Terminal connectors are one of the basic parts commonly used in automobiles, electrical appliances, electronics and other industries. They are used in large quantities and have a wide range of uses. They are usually processed by high-speed punch presses, and high-speed punch press stamping processes are inseparable from automation equipment.

The materials used in high-speed stamping of terminal connectors have narrow width, relatively thin material thickness, and small feeding steps. The matching of automation equipment should follow the requirements of high-speed and high-precision automation

So how to choose right equipments for press line?

FANTY machinery introduces a complete high-speed punch press line here. Automation equipment required for stamping terminal production line:

Steel Decoiling Machine:

Use a flat feeder. FANTY flat electronic uncoiler is a horizontal decoiler with fast decoiling speed and good stability. The coils can be stacked to save loading time. It is an uncoiler equipment for high-speed stamping of terminal connectors.

Feeder equipment:

Use high-speed clamp feeder. FANTY Machinery high-speed clamp feeder/gripper feeder adopts high-speed punch synchronous transmission, with a speed of up to 1200 times/min. It is an ideal feeder for high-speed punch press terminal stamping. If the feeding speed is not fast, it can also be paired with a high-speed roller feeder.

Terminal collection equipment:

Terminal acquisition equipment: A horizontal light controlled terminal acquisition machine is used to collect finished terminal strips. The horizontal light controlled material receiving machine has a fast material receiving speed and does not directly contact the terminal tape, nor does it burn the surface of the terminal tape. It can cover the terminals with paper tape packaging while collecting them. This series of products is stable and the materials are easy to pick up. Of course, more advanced automatic version changing terminal collectors can also be used.

For irregular terminals, an automatic deflection terminal collector can be used.

Sound insulation and noise reduction equipment:

high-speed punch soundproof box. Terminal stamping uses high-speed punching processing, which is fast. Especially when multiple machines are used together, a lot of noise will be produced. It is suitable to be used with a high-speed punching soundproof box for noise reduction, so that the noise meets environmental protection standards.