Tailored Solutions: Customizing Decoilers for Diverse Industry Needs

- Share

- Issue Time

- Nov 23,2023

Summary

This article delves into the increasing significance of customized solutions in the realm of metal processing as industries continue to diversify.

In the dynamic landscape of metal processing, the demand for precision is ever-evolving. As industries diversify, as the steel coil handling equipment, the role of decoiler becomes increasingly pivotal. This article explores how tailored solutions in the form of customized decoilers address the unique requirements across various sectors, ensuring efficiency, precision, and operational excellence. Let's discover more about decoiler machine in this article below:

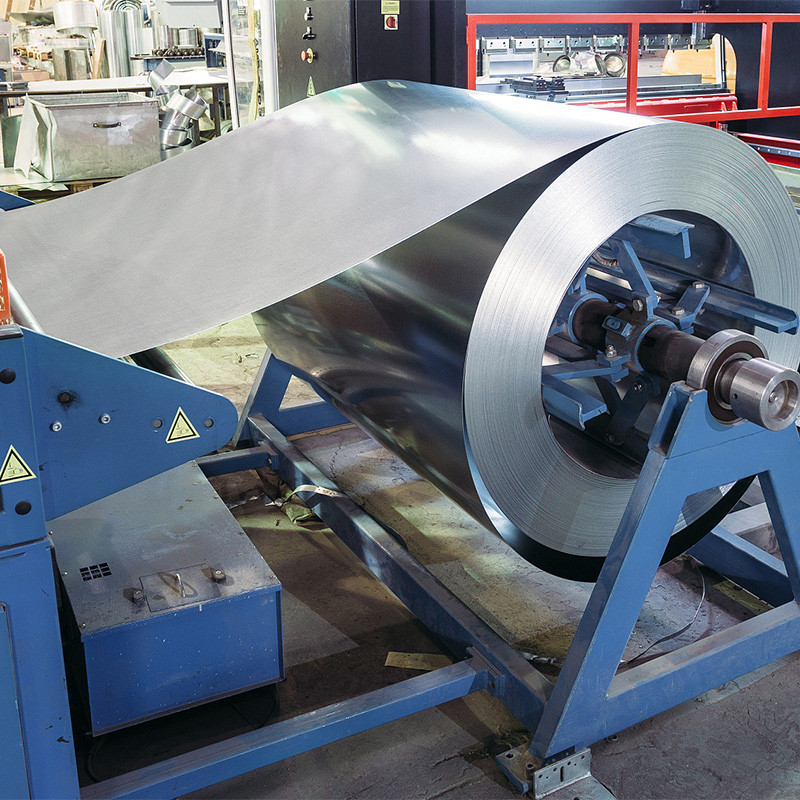

The Crucial Role of Decoilers

Decoilers are the unsung heroes of metal processing, responsible for unwinding coils with precision. In recognizing the diverse needs of industries, customizing decoilers becomes paramount to meet specific challenges efficiently. Learn more about decoiler machine here.

Send inquiry to fanty@sz-fanty.com

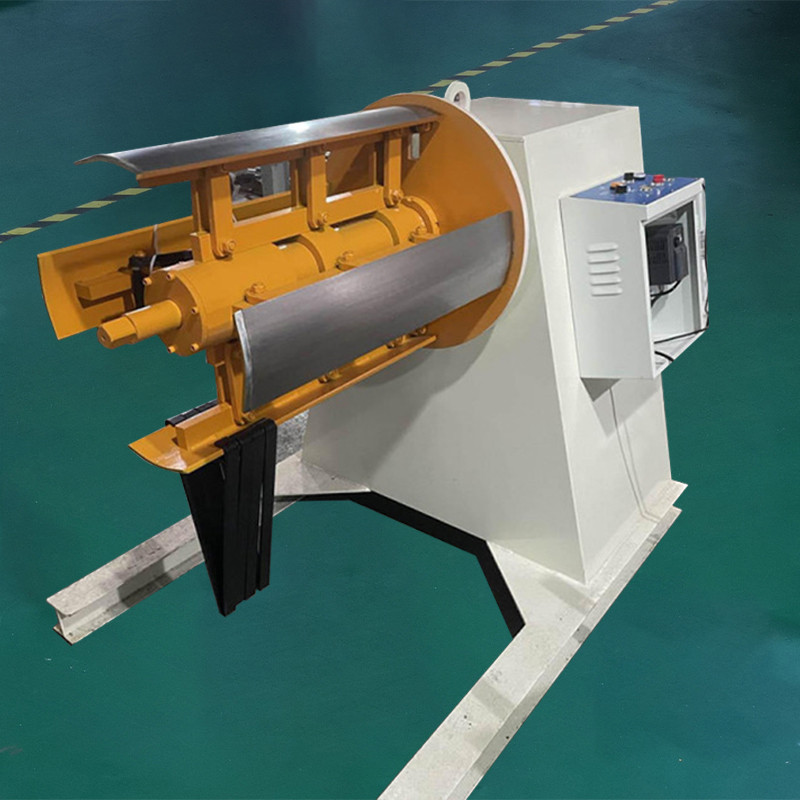

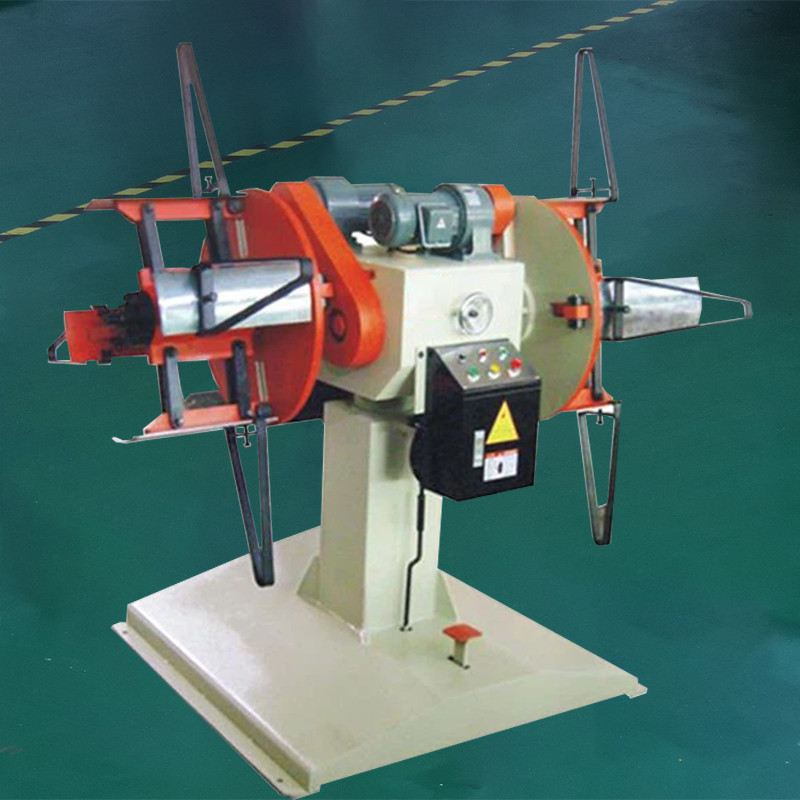

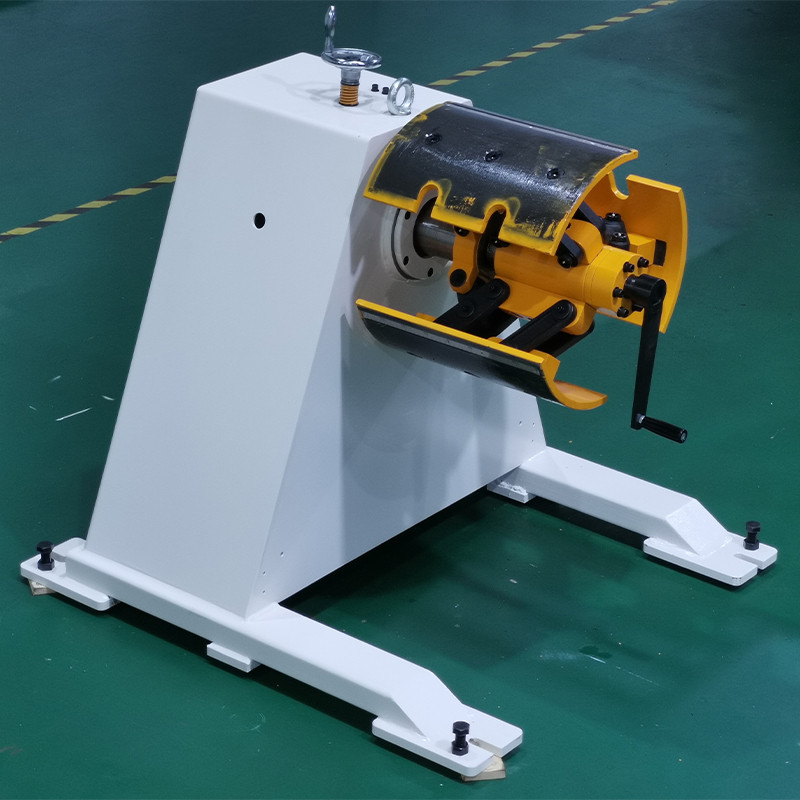

What Steel Decoiler/Uncoiler Does Fanty has?

Key Components of Customized Decoilers

* Material Compatibility:

Customized decoilers consider the material type and thickness, ensuring compatibility and optimal performance for diverse metals, from lightweight alloys to heavy-duty steel.

* Width and Diameter Adjustments:

Addressing industry-specific coil dimensions, tailored solutions allow for adjustments in width and diameter, accommodating various coil sizes for seamless processing.

Meeting Industry-Specific Challenges

*Automotive Sector:

Custom decoilers designed for the automotive industry integrate features that cater to the precision demands of manufacturing components ranging from body panels to intricate parts.

*Aerospace Manufacturing:

In aerospace, where materials are often specialized alloys, customized decoilers provide the necessary adaptations to handle these unique materials with utmost precision.

Advanced Technologies in Customized Decoilers

* Automation and Robotics:

Tailored solutions leverage automation and robotics, streamlining processes and reducing dependence on manual intervention, contributing to enhanced efficiency.

Operational Efficiency and Cost Optimization

* Reduced Downtime:

By aligning decoiler specifications with industry needs, tailored solutions minimize downtime during material changeovers, maximizing operational efficiency.

* Material Waste Reduction:

Precision customization ensures accurate material feed, reducing waste and contributing to cost-effectiveness and sustainability goals.

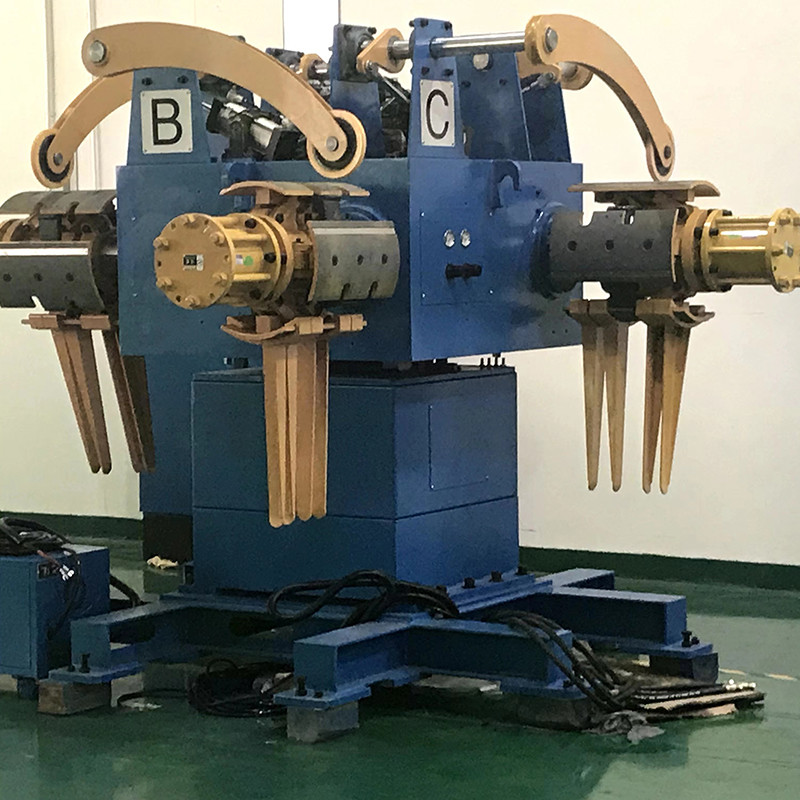

Customized Decoiler Cases

Conclusion

Elevating Industry Standards with Custom Decoilers

As industries continue to diversify, the need for tailored solutions in metal processing becomes imperative. Customized decoilers play a crucial role in elevating industry standards, providing the flexibility and precision required to navigate the unique challenges of diverse sectors. Embracing these solutions not only ensures efficient metal processing but positions companies at the forefront of technological advancements in the ever-evolving landscape of metalworking.