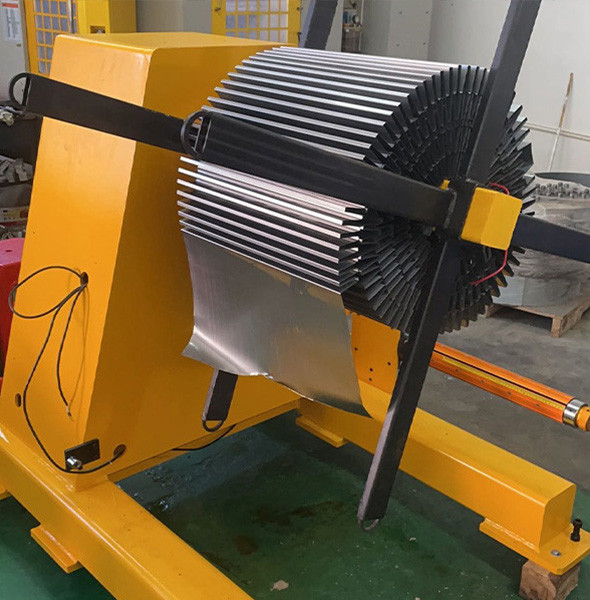

A customized uncoiler made especially to wind soft fabrics

- Share

- Issue Time

- Jan 3,2024

Summary

FANTY introduces a revolutionary customized uncoiler tailored for rewinding soft materials.

The decoiler is also called the uncoiler for steel coiler handling equipment. Currently, the uncoiler is also frequently used as recoiler to rewind various soft materials due to their sticking difficulty and softness; therefore, the uncoiler features a material tensioning guiding device. Through the operator's observation, this guide device typically keeps track of the tensioning and guiding material's condition. The operator must halt the material guiding activity when the material guiding material is excessively tight or loose.

Customized uncoiler specially designed as recoiler for rewinding soft materials

However, because the operator may easily put off identifying issues, this manual control method frequently results in an expansion of material loss. As a result, there is a drawback in that the monitoring is more expensive to produce and lacks real-time accuracy. Simultaneously, there are more strict requirements on the error value of looseness and tightness during the material guidance process for various reeled final products that require high precision. Therefore, employing staff monitoring techniques will make it challenging for the uncoiler to achieve the product's precise standards.

Due to this, FANTY created a unique decoiler specifically designed as recoiler for rewinding soft materials. This recoiler offers four performance benefits over conventional uncoilers now available on the market:

1. The tailored uncoiler's material guidance device is made to resemble a reflex. This design can significantly improve the work efficiency and quality by making the material harder to stick to and pull during the tensioning and conveying process.

2. A module for over-tight induction braking is fitted with the specially designed uncoiler. The uncoiler's driving roller may automatically alter its speed to relieve the pressing state of the material when its tensioning and guiding state becomes excessively tight and quick. By doing this, you can successfully stop the uncoiler from shrinking and deforming as a result of too much strain during rewinding. Furthermore, the material's tensioning and guiding states are regulated within a narrow error range, significantly enhancing the uncoiler's rewinding accuracy to satisfy the demands of high-precision products.

3. The configuration of the uncoiler that was specially built and fitted with an over-tight sensing brake module. It can detect and release the material's urgent situation automatically, saving money on labor costs and successfully averting the occurrence of defective rates—a function more in line with industry standards.

4. There is an anti-tangle induction braking module installed on the customized uncoiler. It can identify when the material's tensioning and guiding condition is too slow and, in real time, stop or reduce the speed of the uncoiler's driving roller to bring the material's tensioning and guiding back to normal. By doing this, the uncoiler's entanglement can be avoided when rewinding the material.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder