A light-controlled uncoiler allows for exact uncoil control.

- Share

- Issue Time

- Jan 4,2024

Summary

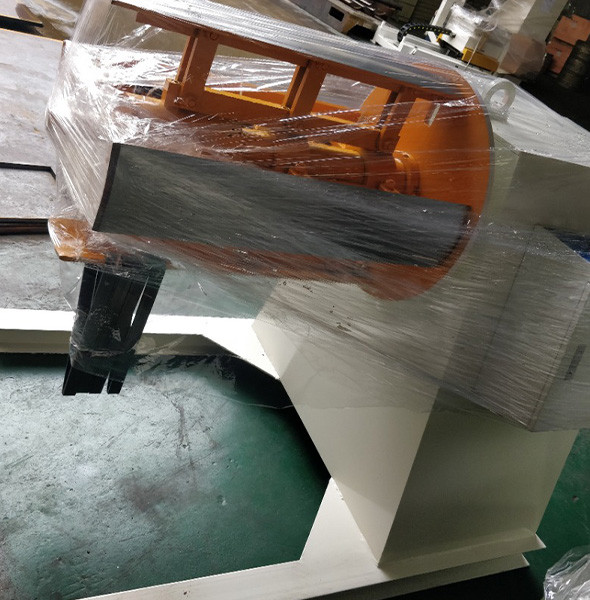

FANTY's light-controlled uncoiler revolutionizes automatic production in stamping.

Currently, coil materials are required for stamping and shearing processing to achieve automated production. Since the uncoiler, also we call decoiler is a unique steel coil handling equipment designed to transport coil materials, it has become a popular tool.

Due to its benefits, which include a huge load capacity, a wide range of material thickness and width applications, and unique customisation, the decoiler has become the industry standard.

An induction rack is used to control a typical decoiler. Because of the metal's inherent gravity, when the decoiler conveys a coil of metal, the metal will arc during transmission, and the uncoiler will be programmed to halt as soon as it comes into contact with the induction rack. In order to provide completely automatic control over the uncoil process, the uncoiler operates automatically after departing.

As the steel coil handling equipment, however, there are flaws in this type of typical uncoiler. Two things must happen: first, the material needs to be formed of metal; second, the material's sag height is influenced by the uncoiler's uncoiling speed, which can cause the material to tighten or loosen.

Of them, material loosening occurs when the uncoiler's speed is high because it causes the material's sag height to rise. Reduced material sag height results from a slow uncoiler speed; this straightens the material and, in extreme circumstances, may even cause damage to the uncoiler.

FANTY created a light-controlled uncoiler to essentially address the flaws in uncoilers. It converts the induction rack into a multi-group photoelectric switch control, which uses the photoelectric switch to sense the material's sag height and adjusts the uncoiler's speed accordingly. This has the benefit of actually realizing exact control over the uncoiler, which solves the material tension or loosening issue and increases the efficiency of stamping production.

For any questions or the solution for steel coil handling equipment, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder