Maintaining Decoilers: Strategies for Longevity and Performance Optimization

- Share

- Issue Time

- Apr 2,2024

Summary

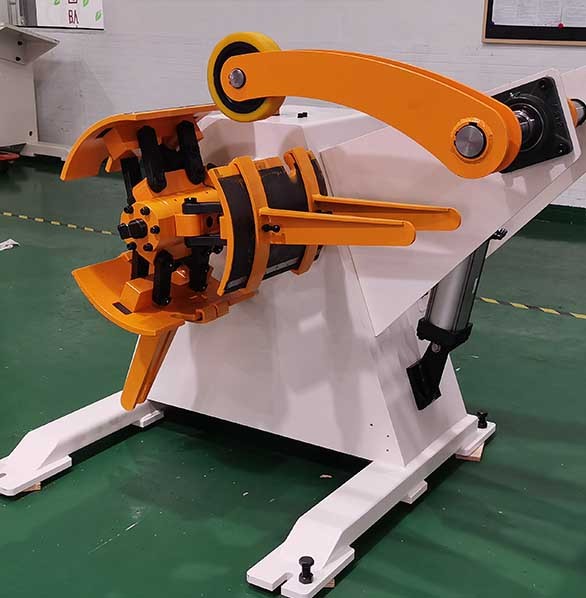

Proper maintenance is essential to ensure the longevity and optimal performance of decoilers in manufacturing environments.

Proper maintenance is essential to ensure the longevity and optimal performance of decoilers in manufacturing environments. By implementing proactive maintenance strategies, manufacturers can minimize downtime, reduce repair costs, and prolong the service life of their equipment. In this article, we explore effective maintenance practices for decoilers, focusing on key components and preventive measures.

Regular Inspection:

Scheduled inspections of critical components, such as bearings, gears, and hydraulic systems, are essential to identify potential issues before they escalate into major problems. Visual inspections and functional tests help detect signs of wear, misalignment, or damage, allowing for timely corrective action.

Lubrication:

Proper lubrication of moving parts is vital to reduce friction, minimize wear, and maintain operational efficiency. Using the appropriate lubricants in accordance with manufacturer recommendations ensures optimal performance and extends the service life of decoiler components.

Cleaning and Debris Removal:

Accumulated dirt, debris, or metal shavings can impair the functionality of decoilers and lead to performance degradation. Regular cleaning of the machine surfaces, as well as debris removal from critical areas such as rollers and guides, prevents obstructions and ensures smooth material feed.

Training and Operator Awareness:

Providing comprehensive training to operators on proper decoiler operation, maintenance procedures, and safety protocols is crucial for maximizing equipment performance and minimizing the risk of accidents. Operator awareness of potential hazards and proactive intervention in case of abnormal machine behavior contribute to a safe and efficient working environment.

In conclusion, proactive maintenance practices are essential for preserving the integrity and performance of decoilers in industrial settings. By adhering to scheduled inspections, implementing proper lubrication routines, and fostering operator competence, manufacturers can optimize equipment reliability and productivity, thereby achieving long-term success in their operations.

More decoiler information, pls click visit us: https://www.decoilerfeeder.com/products2128912/Decoiler.htm