Elevating Metal Sheet Stamping Efficiency through Advanced Recoiling Techniques

- Share

- Issue Time

- May 10,2024

Summary

Boost metal sheet stamping efficiency with advanced recoiling techniques, improving material utilization, precision, and production speed. Reduce setup times & maximize outcomes with modern equipment.

In the realm of metal sheet stamping, efficiency and precision are paramount for achieving optimal results in manufacturing processes. Advanced recoiling techniques have emerged as a game-changer in the industry, offering enhanced productivity, accuracy, and material utilization. In this comprehensive guide, we explore how the implementation of advanced recoiling techniques can elevate metal sheet stamping efficiency to new heights, revolutionizing the way manufacturers approach sheet metal processing.

The Significance of Recoiling Techniques in Metal Sheet Stamping

Recoiling techniques play a crucial role in metal sheet stamping operations by enabling the efficient handling and processing of coiled metal sheets. By utilizing advanced recoiling methods, manufacturers can streamline production workflows, minimize material waste, and enhance the overall quality of stamped components. The precision and control afforded by recoiling techniques contribute to improved productivity and cost-effectiveness in metal fabrication processes.

Key Benefits of Advanced Recoiling Techniques in Metal Sheet Stamping

1. Enhanced Material Utilization

Advanced recoiling techniques optimize the use of metal sheets, reducing waste and maximizing material efficiency in stamping operations.

2. Improved Precision and Consistency

By maintaining tight tolerances and uniformity during recoiling, manufacturers can achieve greater precision and consistency in stamped parts, ensuring high-quality end products.

3. Increased Production Speed

The automation and efficiency of advanced recoiling processes enable faster production cycles, leading to higher output rates and improved manufacturing throughput.

4. Minimized Setup and Changeover Times

Recoiling techniques streamline setup and changeover procedures, allowing for quick transitions between different sheet metal materials and thicknesses, thereby reducing downtime and enhancing operational efficiency.

Implementing Advanced Recoiling Techniques for Optimal Metal Sheet Stamping Efficiency

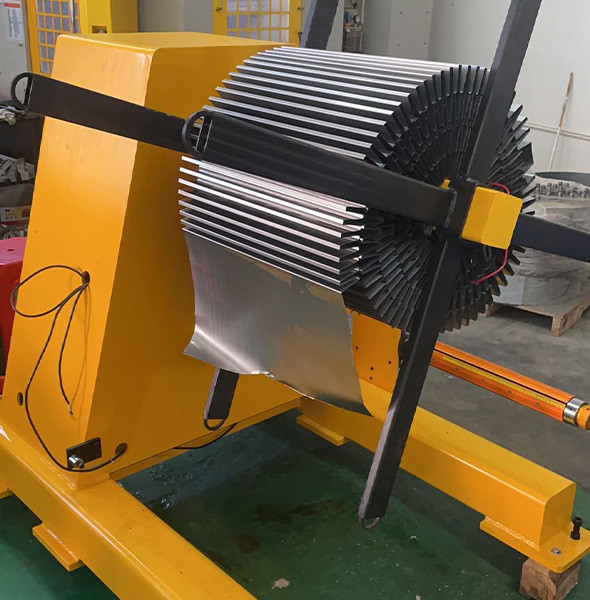

Invest in Modern Recoiling Equipment: Actually, a recoiler is opposite working mode comparing to a decoiler machine (a decoiler is designed for a steel coil uncoiling). Upgrade to state-of-the-art recoiling machinery equipped with advanced automation features and precision controls to optimize material handling and processing.

Utilize Real-time Monitoring Systems: Implement monitoring systems that provide real-time feedback on recoiling parameters such as tension, alignment, and speed to ensure consistent and accurate recoiling operations.

Integrate Quality Control Measures: Incorporate quality control checkpoints throughout the recoiling process to identify and rectify any deviations or defects promptly, maintaining product quality and integrity.

Train Personnel on Recoiling Best Practices: Provide comprehensive training to operators and technicians on the proper operation and maintenance of recoiling equipment to maximize efficiency and minimize downtime.

By embracing advanced recoiling techniques and leveraging cutting-edge technology in metal sheet stamping processes, manufacturers can achieve unparalleled efficiency, precision, and productivity in their operations. Elevate your metal sheet stamping capabilities with advanced recoiling techniques and stay ahead in the competitive landscape of the manufacturing industry.