Enhancing Sheet Metal Processing Efficiency with Double Head Decoilers

- Share

- Issue Time

- May 17,2024

Summary

Double head decoilers versatility and flexibility cater to various coil sizes and materials, ensuring seamless workflow and superior product quality.

In the realm of sheet metal processing, efficiency is key to maintaining a competitive edge in the industry. One of the critical components that can significantly impact efficiency is the uncoiling process. Traditional uncoilers often pose challenges in terms of speed, reliability, and overall productivity. However, with the advent of double head decoilers, manufacturers now have a game-changing solution at their disposal.

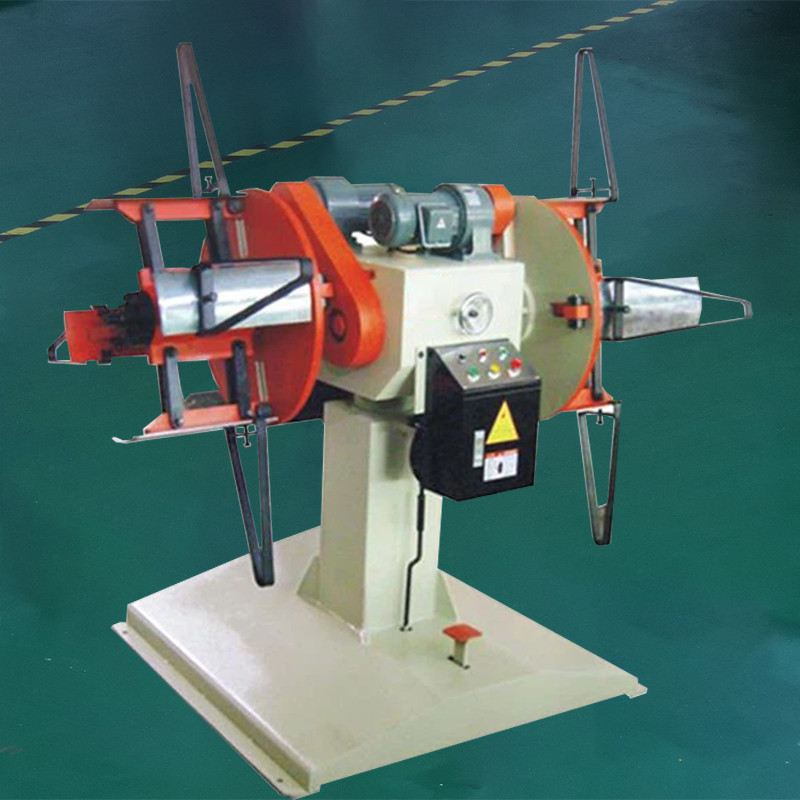

Understanding the Double Head Decoilers

Double head decoilers are innovative machines designed to streamline the uncoiling process by allowing for continuous operation. Unlike their single station counterparts, double station uncoilers feature two separate mandrels, enabling the loading of a new coil while the other is still in use. This dual mandrel design eliminates downtime for coil changes, resulting in a seamless and uninterrupted workflow.

Benefits of Double Station Decoilers

1. Increased Productivity

By enabling continuous operation, double head decoilers significantly boost productivity levels. The ability to load a new coil without interrupting the processing line ensures maximum uptime and output.

2. Enhanced Efficiency

With faster coil changeovers and minimal downtime, manufacturers can achieve higher efficiency in their sheet metal processing operations. This increased efficiency translates to cost savings and improved overall performance.

3. Improved Material Handling

double head decoilers offer superior material handling capabilities, allowing for smoother and more precise feeding of coils. This results in reduced waste, fewer errors, and enhanced product quality.

4. Versatility and Flexibility

These advanced uncoilers are designed to accommodate a wide range of coil sizes and materials, providing manufacturers with greater flexibility in their production processes. Whether working with thin or thick gauge materials, double head decoilers deliver consistent performance.

Implementing Double Head Decoilers in Sheet Metal Processing

Integrating double head decoilers into your sheet metal processing line is a strategic investment that can yield significant returns. By optimizing the uncoiling process, manufacturers can streamline their operations, increase output, and stay ahead of the competition.

In conclusion, the adoption of double head decoilers represents a paradigm shift in sheet metal processing, offering unparalleled efficiency, productivity, and versatility. By leveraging this advanced technology, manufacturers can elevate their operations to new heights and achieve greater success in today's competitive market landscape.