Elevating Sheet Metal Processing Efficiency with Double Station Uncoilers

- Share

- Issue Time

- Jul 10,2024

Summary

Maximize the efficiency of your sheet metal processing operations with double head decoiler and experience a new level of productivity.

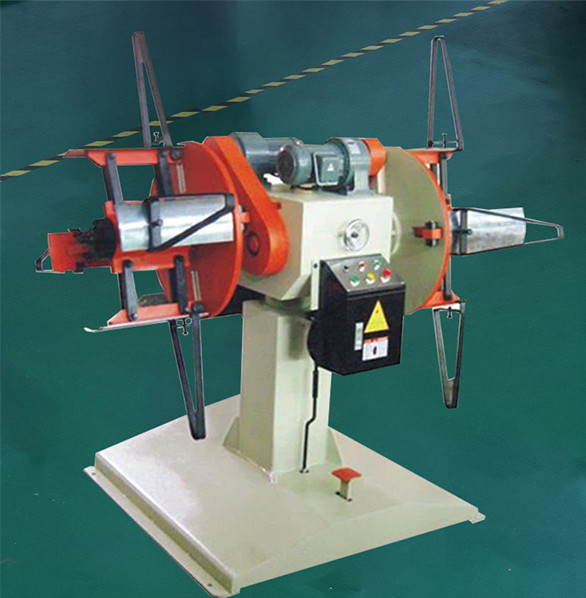

In the sheet metal processing, the utilization of double head decoiler plays a pivotal role in enhancing efficiency and productivity. As the steel coil handling equipment, this type decoiler machine is designed to streamline the material feeding process, allowing for continuous operation and improved workflow. In this comprehensive guide, we will explore the key features, benefits, and best practices associated with double head decoiler, highlighting its significance in optimizing sheet metal processing operations.

Understanding the Role of Double Head Decoiler in Sheet Metal Processing

Seamless Material Feeding

As the steel coil handling equipment, Double head decoiler is engineered to provide a seamless and uninterrupted supply of metal coils to downstream processing equipment. By accommodating two coils simultaneously, this type decoiler machine ensures a constant feed of material, minimizing downtime and maximizing productivity.

Enhanced Flexibility

As the steel coil handling equipment, one of the key advantages of Double head decoiler is its ability to handle multiple steel coil sizes and types, offering greater flexibility in sheet metal processing operations. This versatility allows manufacturers to switch between different materials and thicknesses with ease, optimizing production efficiency.

Improved Coil Changeover

Double head decoiler facilitates quick and efficient steel coil changeovers, reducing setup times and enhancing operational efficiency. The dual station design enables operators to prepare the next coil while the current one is still in use, eliminating delays and improving overall workflow.

Benefits of Double Head Decoiler in Sheet Metal Processing

Increased Productivity

By enabling continuous material feeding and rapid coil changeovers, Double head decoiler significantly boosts productivity in sheet metal processing operations. The seamless workflow and reduced setup times result in higher output and improved efficiency.

Enhanced Material Utilization

As the steel coil handling equipment, Double head decoiler helps minimize material waste by optimizing the feeding and handling of metal coils. The ability to switch between different coil sizes and types ensures maximum material utilization, leading to cost savings and improved sustainability.

Superior Coil Control

With precise tension control and alignment features, Double head decoiler ensures consistent and accurate feeding of metal coils. This results in higher quality finished products with minimal material distortion or misalignment, enhancing the overall production output.

Fanty Machinery Produces Double Head Decoiler

As the manufacturer of Double head decoiler, Fanty Machinery is providing the customized decoiler machine solution to our clients. More details about double head decoiler, pls click here.

Fanty Machinery steel coil handling equipment caters to diverse steel coil handling needs. Any inquiry to customized decoiler machine or other steel coil handling equipment, pls contact us fanty@sz-fanty.com

Best Practices for Maximizing Double Head Decoiler Performance

Regular Maintenance and Inspection

To ensure optimal performance, Double head decoiler should undergo regular maintenance and inspection. This includes lubrication of moving parts, alignment checks, and calibration of tension control systems to maintain efficiency and reliability.

Operator Training and Safety

Proper training of operators is essential for safe and efficient operation of Double head decoiler. Operators should be familiar with the decoiler machine's controls, safety features, and maintenance procedures to prevent accidents and ensure smooth workflow.

Integration with Automation Systems

Integrating Double head decoiler with automation systems such as PLCs and sensors can further enhance efficiency and productivity. Automated control of feeding parameters and coil changeovers streamlines operations and minimizes human error for optimized performance.

Conclusion

In conclusion, Double head decoiler is indispensable tools for elevating sheet metal processing efficiency, offering a range of benefits including increased productivity, enhanced flexibility, and superior material utilization. By understanding the role of Double head decoiler and implementing best practices for their utilization, manufacturers can optimize their sheet metal processing operations and achieve greater efficiency and quality in their production processes.