What Is The Essential Role of Decoilers in Automated Production Lines ?

- Share

- Issue Time

- Sep 19,2024

Summary

Check this article to understand the essential functions and benefits of decoilers and enhance production capabilities.

In the fast-paced world of manufacturing, particularly within the stamping and shearing industries, the efficiency of production lines is paramount. One of the critical components that significantly enhances this efficiency is the decoiler, also called uncoiler machine. This article delves into the vital role of decoilers in automated production lines, highlighting their functionality, benefits, and the impact they have on overall productivity.

Understanding Decoilers:

A Key Component in Stamping Manufacturing

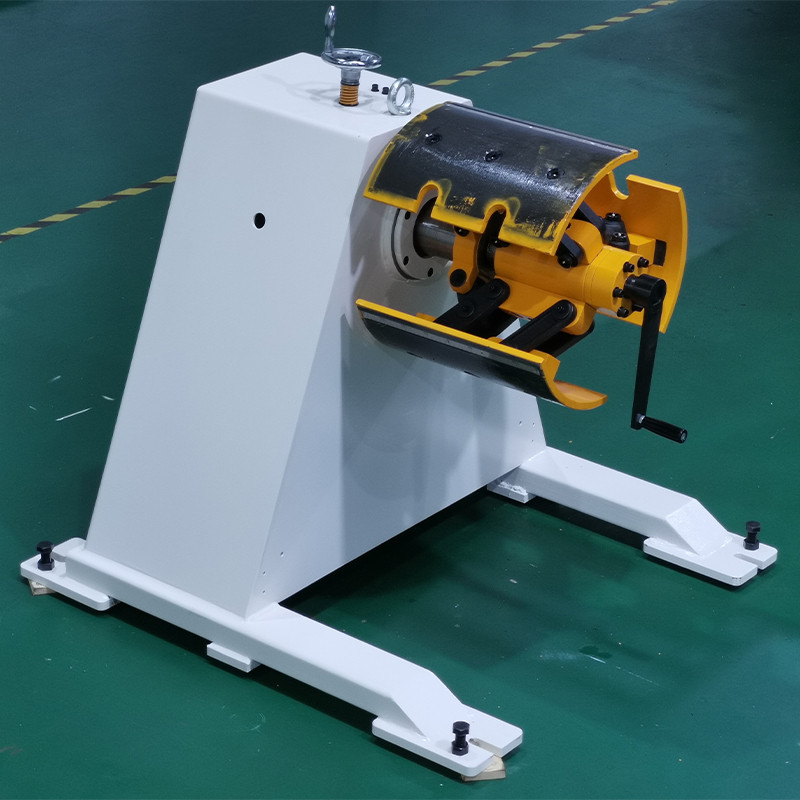

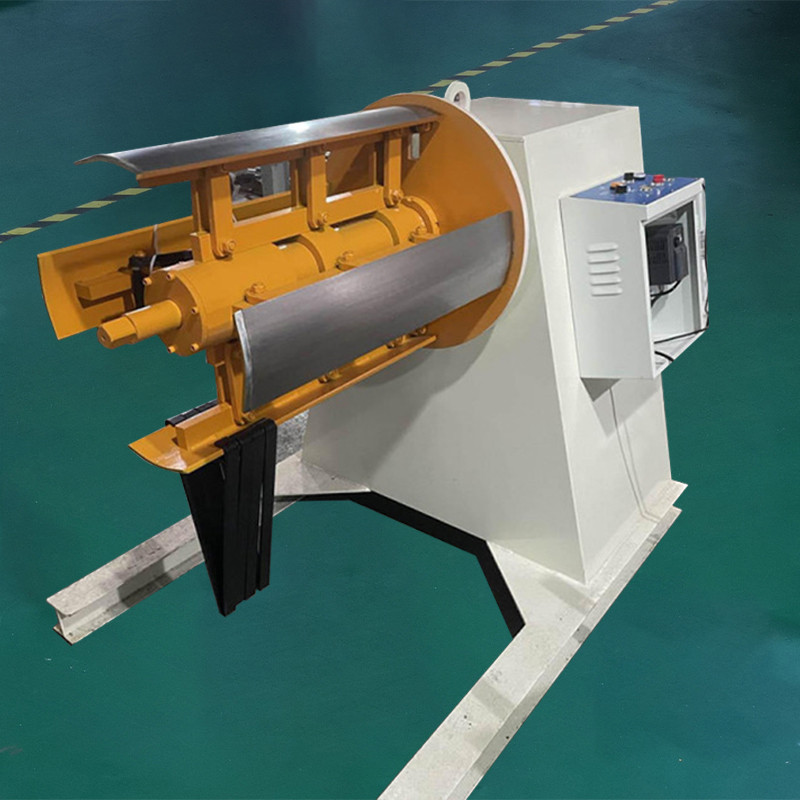

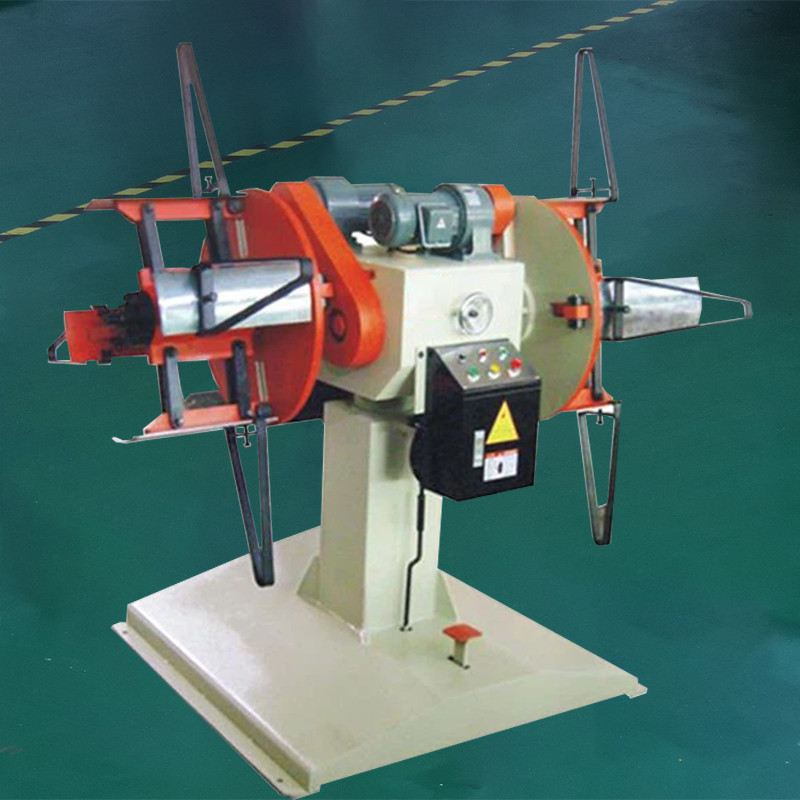

Decoilers are machines designed to unwind coils of material, such as metal sheets or strips, in a controlled manner. They are essential for feeding raw materials into automated production lines, ensuring a smooth and uninterrupted workflow. By providing a consistent supply of material, decoilers help maintain the pace of production, reducing downtime and increasing output.

Types of Decoilers

Decoilers come in various types, each suited for specific applications. The most common types include:

The Benefits of Using Decoilers in Automated Production Lines

Enhanced Efficiency

Decoilers streamline the production process by ensuring a steady supply of material. This continuous feed minimizes interruptions, allowing machines to operate at optimal speeds. As a result, manufacturers can achieve higher output rates and meet production targets more effectively.

Improved Safety

Automated decoilers reduce the need for manual handling of heavy coils, significantly lowering the risk of workplace injuries. By automating the uncoiling process, workers can focus on other critical tasks, enhancing overall safety in the production environment.

Consistent Material Handling

Decoilers provide precise control over the unwinding process, ensuring that materials are fed into the production line at a consistent rate. This uniformity is crucial for maintaining product quality and reducing waste, as variations in material feed can lead to defects in the final product.

Versatility Across Industries

Decoilers are not limited to a single industry; they are versatile machines used in various sectors, including automotive, aerospace, and construction. Their ability to handle different materials and coil sizes makes them an invaluable asset in any automated production line.

Integrating Decoilers into Your Production Line

Choosing the Right Decoiler

Selecting the appropriate decoiler for your production line is critical. Factors to consider include:

* Material Type: Ensure the decoiler is compatible with the materials you will be using.

* Coil Size and Weight: Choose a decoiler that can handle the dimensions and weight of your coils.

* Production Volume: For high-volume operations, automatic or heavy-duty decoilers are recommended.

Maintenance and Care

Regular maintenance of decoilers is essential to ensure their longevity and optimal performance. Key maintenance practices include:

* Routine Inspections: Regularly check for wear and tear on components.

* Lubrication: Keep moving parts well-lubricated to prevent friction and overheating.

* Calibration: Periodically calibrate the decoiler to ensure accurate material feed rates.

Conclusion

Decoilers play a crucial role in enhancing the efficiency and safety of automated production lines in the stamping and shearing industries. By providing a consistent and controlled supply of materials, they contribute significantly to the overall productivity of manufacturing operations. Investing in the right decoiler and maintaining it properly can lead to substantial improvements in production efficiency and product quality.