Top Innovations in Decoiler Feeder Systems for 2025

- Share

- Issue Time

- Jan 13,2025

Summary

Innovative decoiler feeder systems enhance material handling with compact designs, smart controls, and energy-efficient features. These advancements boost production efficiency and sustainability.

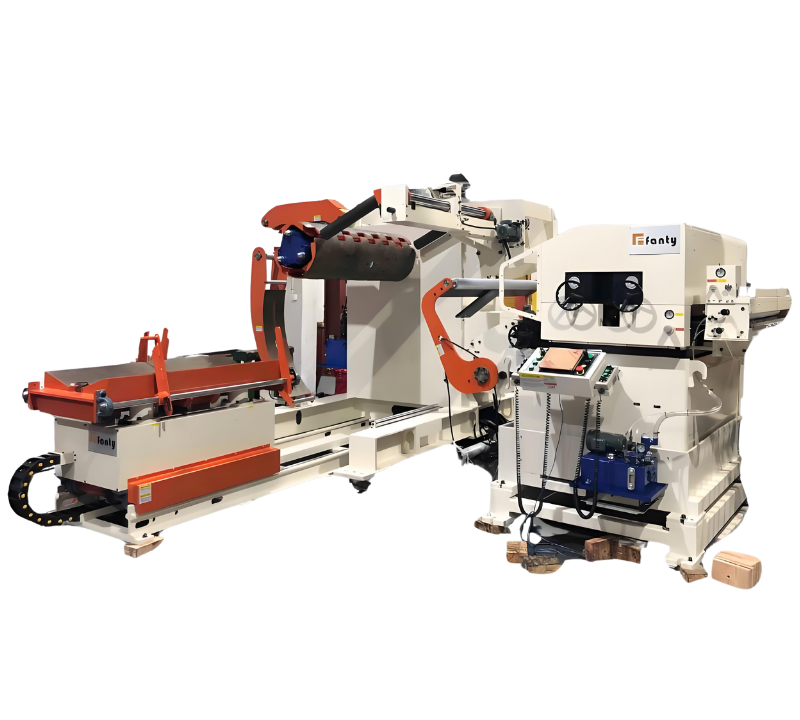

Decoiler feeder systems are the backbone of automated manufacturing lines, ensuring a smooth flow of materials to stamping machines and presses. With 2025 on the horizon, manufacturers are witnessing groundbreaking innovations in decoiler feeder systems, from compact designs to advanced automation features. These innovations are improving material handling, reducing downtime, and driving production efficiency. This article delves into the latest trends shaping the future of decoiler feeder systems.

Why Decoiler Feeder Systems Matter in Modern Manufacturing

Key Innovations to Watch in 2025

* Compact Designs: New systems feature space-saving configurations that maximize floor space while maintaining high performance.

* Smart Controls: Advanced servo-driven controls improve feeding accuracy and allow for customizable operations.

* Sustainability Focus: Energy-efficient designs and recyclable materials are becoming standard features, reducing the carbon footprint of manufacturing lines.

Benefits of Investing in Modern Decoiler Feeder Systems

Adopting the latest decoiler feeder systems allows manufacturers to:

* Achieve higher production speeds without compromising quality.

* Minimize downtime through predictive maintenance technologies.

* Handle a wider range of coil sizes and materials with ease.

Conclusion

As manufacturing demands grow, investing in the latest decoiler feeder systems is essential to stay competitive. With innovations in design, automation, and sustainability, these systems will continue to drive efficiency and reliability in production lines.