How Metal Stamping Automation Improves Efficiency in Manufacturing ?

- Share

- Issue Time

- Jan 20,2025

Summary

Metal stamping automation transforms production by enhancing efficiency through automated stamping systems. Learn how steel coil handling optimizes operations and reduces downtime in manufacturing.

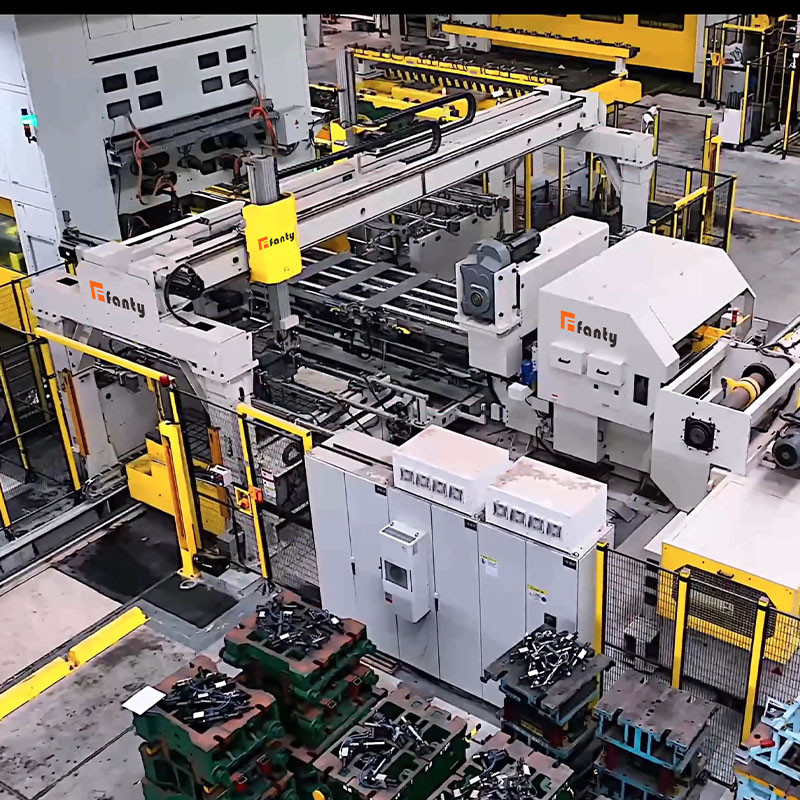

As a leading metal stamping automation solutions provider, we understand the critical role that automation plays in enhancing manufacturing efficiency. Automated stamping systems, particularly those designed for steel coil handling, have revolutionized industries ranging from automotive to home appliances.

The Power of Stamping Automation

Stamping automation is not just about replacing manual labor; it’s about creating precision, speed, and cost savings. By integrating decoiler and feeder systems, manufacturers can streamline their production lines, reduce material waste, and increase throughput. The use of high-tech stamp presses further ensures that every stamped part is consistent and accurate, even in high-volume runs.

The Role of Advanced Coil Handling

Automated coil handling systems are central to the performance of any stamping line. With systems designed to handle various coil sizes and weights, manufacturers can ensure continuous operation without downtime for coil loading or alignment. These systems are equipped with advanced technology to straighten and feed coils precisely into the stamping press, ensuring smooth and uninterrupted operations.

Applications Across Industries

From automotive manufacturing to electronics production, stamping automation has proven essential in various sectors. For example, in automotive manufacturing, automated stamping systems help produce intricate car parts with exceptional precision. This reduces production time, improves part quality, and ultimately lowers costs.

Conclusion

As industries continue to evolve, the need for precision stamping technology and automation in metalworking becomes more pronounced. Companies embracing industrial automation solutions are setting the stage for more efficient, cost-effective production lines. Investing in stamping press automation today ensures businesses stay ahead in an increasingly competitive global market.