How Stamping Automation Improves Efficiency in Manufacturing ?

- Share

- Issue Time

- Jan 21,2025

Summary

Stamping automation enhances manufacturing efficiency by improving accuracy, reducing downtime & lowering labor costs. learn how metal stamping automation equipment boosts production in this article.

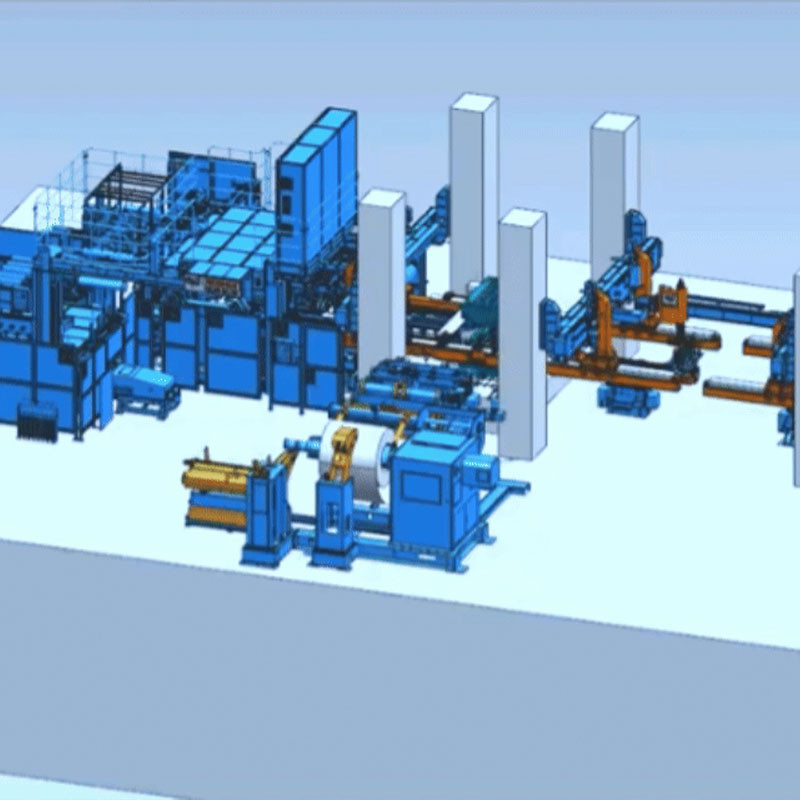

In the manufacturing industry, particularly in steel coil handling, stamping plays a crucial role in shaping and cutting materials into precise forms. As industries evolve, the integration of stamping automation has become a key factor in improving efficiency, reducing costs, and enhancing product quality. This article explores how metal stamping automation can drive efficiency across production lines, providing significant advantages for businesses that want to stay competitive in a fast-paced market.

1. The Shift Towards Stamping Automation

Stamping automation refers to the use of advanced technology to control stamping presses and material handling systems, such as automated decoilers, feeders, and straighteners. Traditional manual stamping processes are labor-intensive, prone to errors, and can lead to higher operational costs. By transitioning to automated systems, manufacturers can eliminate much of the inefficiency caused by manual operations. The use of automated systems ensures that materials are processed more quickly and accurately, reducing cycle times and increasing output per hour.

2. Streamlined Production with Less Downtime

One of the main benefits of stamping automation is the reduction in downtime. Automated stamping presses and feeding systems are designed to operate continuously with minimal human intervention. With the integration of robotic arms, automated coil feeding and straightening systems can handle steel coils more efficiently, reducing delays between operations. Automated systems can also be integrated with servo-driven stamping presses to adjust stamping force and speed in real-time, based on the specific requirements of each part. This flexibility improves overall production efficiency, ensuring faster turnaround times.

3. Enhanced Accuracy and Consistency

In manual stamping, the accuracy of the operation is highly dependent on human skill and can vary from one worker to another. Stamping automation solves this issue by ensuring consistent, high-precision stamping, regardless of the number of parts being produced. Automated systems can maintain consistent force, speed, and material feed rates, ensuring that each stamped part meets exact specifications. This reduces waste caused by defective products and ensures high-quality parts, which is especially critical in industries like automotive, aerospace, and electronics, where precision is a must.

4. Reduced Labor Costs and Human Error

The integration of automation reduces the reliance on manual labor for repetitive and physically demanding tasks. Operators no longer need to manually feed coils or adjust the presses, which allows workers to focus on more complex tasks that require human expertise. Additionally, by reducing human error, manufacturers can prevent costly mistakes that could result in material waste or defective products. With fewer workers handling repetitive tasks, companies can optimize their workforce, which can lead to significant labor cost savings in the long term.

5. Improved Safety in the Workplace

Automating the stamping process also improves workplace safety. Stamping presses, especially those working with heavy coils and high-force equipment, can pose risks to operators. By implementing automation, human workers are kept at a safe distance from hazardous machinery. Robots and automated systems handle the heavy lifting, while workers supervise and manage the operation from a safer position. This not only reduces workplace accidents but also ensures compliance with safety standards and regulations.

6. Increased Production Flexibility

With automated stamping systems, manufacturers gain greater flexibility in production. For example, servo-driven stamping presses can be programmed to perform multiple stamping operations on a single part or handle varying part sizes without requiring manual adjustments. This adaptability makes it easier for companies to produce different parts in smaller batches or rapidly switch between product designs, which is particularly beneficial in industries that demand quick turnaround times, like electronics or automotive.

7. Enhanced Data Integration for Process Optimization

Modern stamping automation systems are equipped with sensors and data collection tools that track machine performance and part quality in real-time. These systems gather data on cycle times, material feed rates, and production output, which can be analyzed to identify inefficiencies or areas for improvement. Manufacturers can use this data to optimize their processes, reduce waste, and predict maintenance needs before a machine fails. By integrating automation with data analytics, businesses can achieve continuous improvement and remain competitive in the ever-evolving manufacturing landscape.

8. Scalability and Long-Term Growth

As businesses grow, their production needs often become more complex. Automated stamping equipment can scale with the company's needs, allowing for smoother expansion. Adding new machines or upgrading existing systems to handle larger volumes or more complex parts becomes easier with automation. This scalability ensures that companies can continue to meet market demand and maintain a high level of efficiency as their operations expand.

Conclusion

Incorporating stamping automation into manufacturing processes is no longer a luxury; it is a necessity for businesses aiming to improve efficiency, reduce costs, and maintain a competitive edge. From increased accuracy and reduced labor costs to improved safety and production flexibility, automation offers numerous benefits that directly impact a company’s bottom line. For industries that rely on high-volume production and precision, like automotive and electronics, stamping automation equipment provides the tools necessary to meet modern manufacturing demands. As technology continues to evolve, manufacturers who embrace automation will not only increase their efficiency but also pave the way for long-term growth and innovation in an increasingly automated world.

By optimizing your stamping processes, you can achieve enhanced productivity, higher-quality products, and reduced operational costs, which will ultimately set your business apart from competitors.