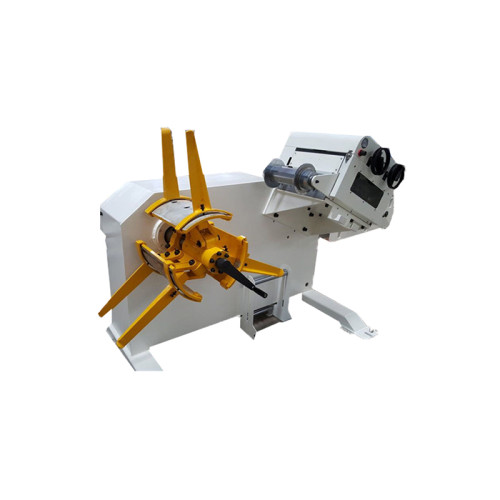

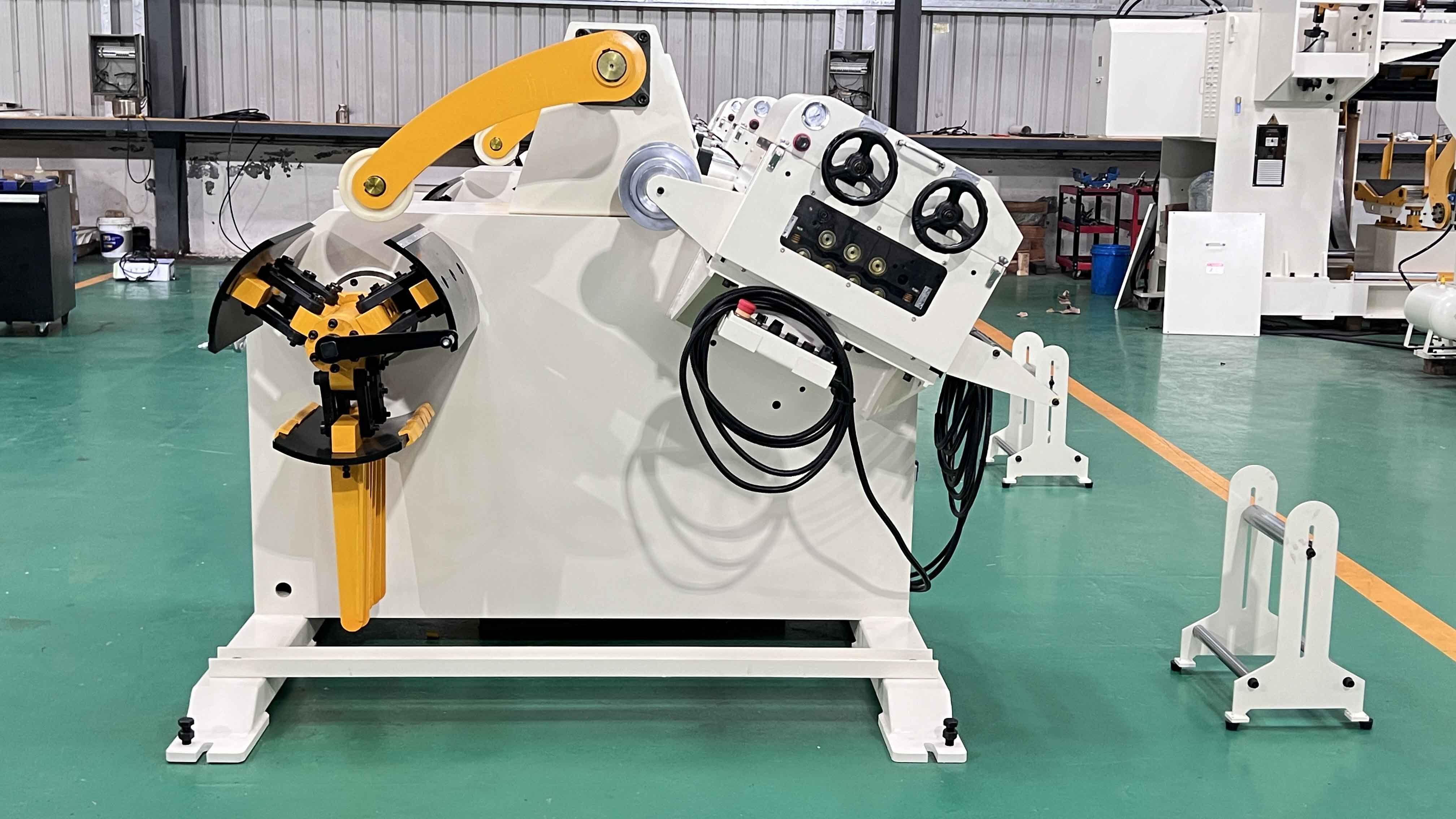

Coil Decoiler Straightener for Auto Components Stamping

- Model

- GL Series Coil Uncoiler Straightener Combo Machine

Item specifics

- Color

- Standard white (other colors are available)

- Payment

- 30% T/T as deposit, rest against shipping

- Certificate

- ISO, CE

Review

Description

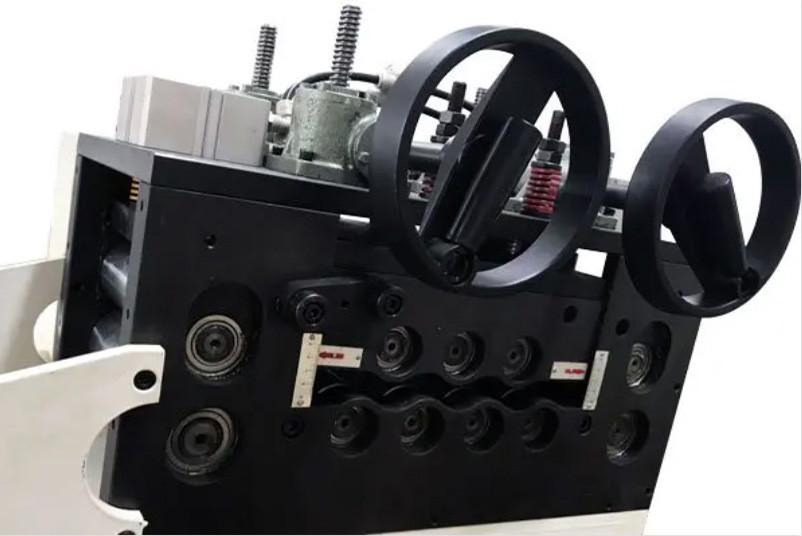

As Coil Decoiler Straightener, Decoiler straightener, also call uncoiler straightener or uncoiler cum decoiler, synchronization is ensured by the integrated construction. In comparison to a traditional straightening machine, this leveling system's pneumatic rod pressing and release system on upper rollers and handwheel roller gap adjustment produce better coil straightening results.

Model | GL-200 | GL-300 | GL-400 | GL-500 | GL-600 |

Coil Width | 200 | 300 | 400 | 500 | 600 |

Coil Thickness | 0.3-3.2 mm | ||||

Coil O.D.(mm) | Ø 460-530 | ||||

Coil I.D.(mm) | Ø 1200 | ||||

Max. load(kg) | 800 | 1000 | 1500 | 2000 | 2000 |

Pinch Rolls (qty) | Inlet 2pcs / Outlet 2pcs | ||||

Straightener Rolls (qty) | Top 3pcs / Down 4pcs | ||||

Mandrel Expansion | Manual | ||||

Line Speed (m/min) | 16 | ||||

Adjustment | Worm and gear fine tuning | ||||

Loop Control | Touch Sensor | ||||

Fanty machine focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

For standard small decoiler, straightener, feeder which go LCL shipping, FANTY will use plastic films cover the equipment, and then fix it into a wooden case.

For the coil feed lines and complete line which go FCL shipping, fanty will fix each part with ropes on the shipping container and then wrapped them with plastic films.

If machines experience any issues within the warranty period while being used "normally," we will send you free components, and we have engineers accessible to service machines abroad.

Yes, we can offer a variety of models.

The machine is guaranteed for one year. Typically, if it breaks down, our specialist will identify the potential cause, according to feedback.