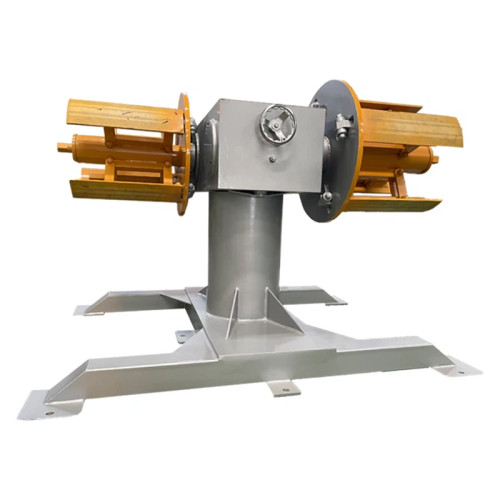

Hydraulic Expansion Double Head Decoiler Machine for Unwinding 300 mm Width Coil

- Model

- DBMT Series Hydraulic Expansion Double Head Uncoiler Machine

Item specifics

- Color

- Standard white (other colors are available)

- Payment

- 30% T/T as deposit, rest against shipping

- Certificate

- ISO, CE

- Customized Service

- Yes

Review

Description

* Steel coil width handling range: 300mm

* Steel coil thickness handling range: 0.35~1.6mm

* Coil I.D: Ø450~530mm

* Coil O.D: 1200mm

* Per side coil Loading Weight:800 kgs

* Mandrel Expansion: Hydraulic Expansion

Model | DBMT-300 |

Coil Width | 300 mm |

Coil Thickness | 0.35 mm – 1.6 mm |

Coil I.D. | Ø450~530mm |

Coil O.D. | Ø1200mm |

Coil Loading Weight | 800 kgs per side |

Mandrel Expansion | Hydraulic Expansion |

Fanty machine focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

A: The sales team must be informed of the precise delivery date. It can be dispatched within five days if we have stock. It will take 30 to 35 days to prepare the goods if they are not already in stock.

What type of transportation do the goods use?

A: You can choose the precise mode of transportation based on your demands, such as by train or by water. The majority of our trade terms are focused on exw, also FOB is available

1. Each year, we participate in a number of exhibitions, and hundreds of customers stop by our stand to speak with us more.

2. Constant online consultation and inquiry help.

4. You are welcome to see our factory.

1. Engineers are available for training in the client's factory.

2. A one-year warranty

3. Round-the-clock technical assistance through phone or email

4. An English user handbook for operating and maintaining the machine

Since we are aware that quality is essential to businesses, we have integrated quality control into every step of the production process, including product development, design, purchasing, processing, assembly, and testing. To prevent any subpar products from being shipped out before delivery, the entire organization participates in quality management. Each equipment has been inspected using the following procedures:

a.100% quality testing, which involves rigorous mechanical assembly and electrical performance tests on every unit before delivery;

b. Before delivery, every machine was checked using a 100% sample, or processed sample;

c. We always strive to provide "ALL FOR CUSTOMERS" service. Advanced management and top-notch service

By enabling us to deliver prompt, effective services and substantially assure product stability, the system effectively provides a guarantee for the regular operation of the system.