How to Maintain an NC Straightener Feeder Machine? Best Practices & Troubleshooting Guide

- Share

- Issue Time

- Feb 3,2026

Summary

Struggling with NC straightener feeder downtime or feeding inaccuracies? Learn essential maintenance best practices, daily/weekly checklists, lubrication tips, common fixes for jamming & precision loss.

How to Maintain an NC Straightener Feeder Machine? Best Practices & Troubleshooting Guide

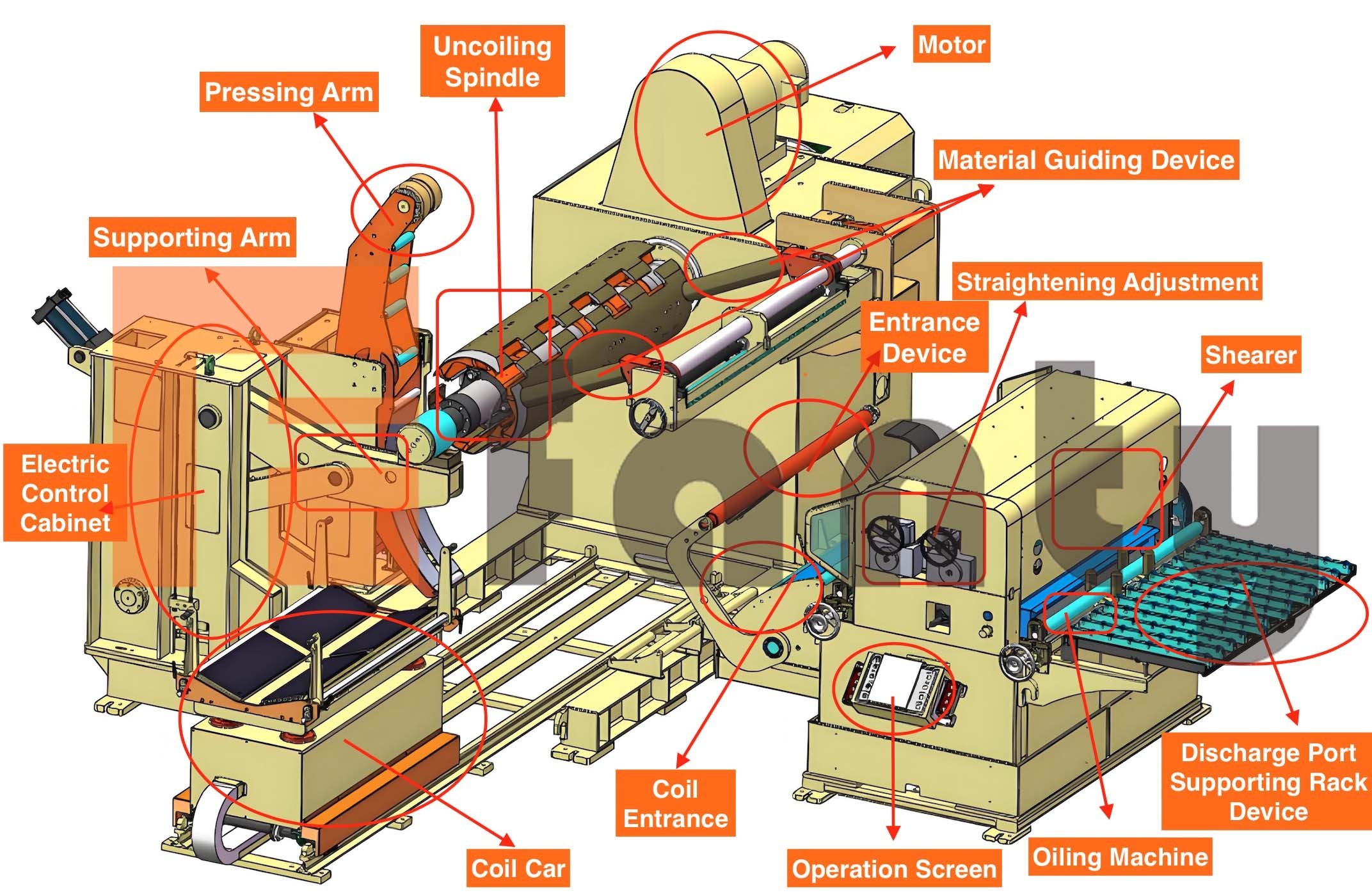

Running an NC straightener feeder (also called NC servo straightener feeder) in your stamping or coil processing line? These machines are fantastic for high-precision feeding and leveling—but when they start jamming, losing accuracy, or causing unexpected stops, production grinds to a halt fast. I've spent years helping factories get these back on track, and the truth is: most issues come down to skipped or inconsistent maintenance. In this practical guide, we'll cover daily/weekly routines, key lubrication points, common troubleshooting (especially jamming and feeding errors), and honest advice on when upgrading to a more advanced model makes sense.

Why Maintenance Matters for NC Straightener Feeders

These integrated machines combine straightening rollers (to remove coil set) with precise NC servo feeding—delivering ±0.05mm accuracy at high speeds. But dirt buildup, dry bearings, misaligned rollers, or neglected servo calibration can quickly cause:

- Jamming or material slippage (especially with oily/burr-edged coils)

- Feeding length errors (±0.2mm+ deviation)

- Vibration, noise, or premature wear on rollers/gears

- Unplanned downtime costing $300–$800/hour in lost production

Good news: 80% of these problems are preventable with a simple, consistent routine. Let's break it down by frequency.

Daily & Weekly Maintenance Checklist (The Non-Negotiables)

Do these every shift or weekly—takes 15–30 minutes but saves hours later.

| Task | Frequency | How-To & Why |

|---|---|---|

| Visual inspection & clean rollers | Daily / Start of shift | Power off, remove dust/oil/debris with soft brush & approved cleaner. Prevents jamming & slippage from buildup. |

| Check roller pressure & alignment | Daily | Ensure even clamping; realign if material pulls to one side. Uneven pressure = feeding errors. |

| Lubricate key points (bearings, gears, pivot arms) | Weekly or every 40–80 hours | Use NLGI #2 grease or manufacturer-spec oil. Dry bearings cause noise & wear. |

| Inspect air/hydraulic pressure & filters | Weekly | Check gauges & replace clogged filters. Low pressure = weak clamping & jams. |

| Servo & electrical check | Weekly | Look for loose wires, error codes on HMI. Recalibrate feed length if off. |

Common Problems & Quick Fixes (Jamming, Inaccuracy & More)

From factory floors I've visited, these are the top issues—and how to solve them fast:

- Jamming / Material Slippage: Clean rollers thoroughly; check for burrs on coil edge or uneven pressure. Adjust air cylinder force evenly. Often fixed in 10–15 mins.

- Feeding Length Inaccuracy: Recalibrate servo parameters via HMI (zero reset, teach mode). Inspect encoder coupling for looseness. Material quality (burrs, oil) is a frequent culprit too.

- Vibration/Noise: Tighten all bolts; lubricate bearings/gears. Worn rollers? Replace in pairs for balance.

- Servo Overheating/Error Codes: Ensure ventilation clear; check drive cooling fan. Update firmware if available.

If problems keep recurring despite good maintenance, it might be time to evaluate an upgrade—more on that below.

When Should You Upgrade Your NC Straightener Feeder?

If you're spending more time fixing than producing, or tolerances are drifting beyond acceptable limits, consider moving to a newer-generation model. Fanty's latest NC straightener feeders feature:

- Self-diagnostic HMI with error logging

- Hardened rollers (HRC60±2) & auto-lubrication options

- High-response servo for ±0.03mm repeatability

- Integrated safety interlocks & remote monitoring

Fanty Machinery has specialized in these machines since 2013. Our 45,000㎡ Dongguan facility and 80+ R&D engineers have delivered precision solutions to over 2,000 lines worldwide—including automotive and appliance leaders like BYD. CE-certified, reliable, and backed by fast parts & support. See our full story on the About Us page—or contact us for a free audit of your current setup.

Quick FAQ for NC Straightener Feeder Owners

Q: How often should I lubricate the rollers and gears?

A: Weekly for moderate use (40–80 operating hours); use only recommended grease to avoid attracting more dust.

Q: Why does my feeder jam only with certain coils?

A: Burrs, oil residue, or inconsistent thickness. Pre-inspect coils and clean rollers more frequently for problem materials.

Q: Is maintenance different for high-speed vs. standard models?

A: Yes—high-speed units need more frequent checks (daily cleaning, bi-weekly lube) due to heat & wear.