What Are the Latest Innovations in Smart Coil Feeding Lines for Industry 4.0 in 2025?

- Share

- Issue Time

- Nov 19,2025

Summary

Dive into 2025's cutting-edge innovations in smart coil feeding lines, from IoT monitoring to AI-driven automation. Expert insights on efficiency gains, with a spotlight on suppliers like Fanty.

I'll never forget the first time I hooked up a basic coil line to a press back in the early 2010s—clunky, noisy, and about as smart as a screen door on a submarine. We'd babysit every feed, tweaking tensions by feel, and any hiccup meant hours of lost output. Fast-forward to now, and Industry 4.0 has flipped the script on smart coil feeding lines, turning those old beasts into connected powerhouses that predict jams before they happen. In 2025, with EV demands cranking up the need for lighter, stronger metals, these innovations aren't just buzzwords—they're the edge keeping shops like yours ahead of the scrap pile.

From digging through the latest trade rags and swapping war stories with floor guys, I've pieced together the real game-changers: IoT brains, AI tweaks, and automation that slashes downtime by 50% or more.

IoT Integration: Your Line's New Nervous System

The big leap in 2025? Embedding sensors across the coil feeding line—from uncoiler mandrels to feeder rolls—that ping real-time data on tension, speed, and wear straight to your dashboard.

AI and Predictive Smarts: Feeding Before It Fails

AI's sneaking in as the quiet hero, crunching sensor feeds to predict when your hydraulic uncoiler might slip or a servo lags—think algorithms spotting patterns from past runs to auto-adjust before the press starves.

Full Automation and Energy Sips: Leaner, Greener Runs

Automation's hitting overdrive with robotic coil loaders and variable-speed drives that ramp down when idle, tying into Industry 4.0's green push—expect 30% energy cuts on lines feeding renewables or HVAC coils.

| Innovation | Key Benefit | 2025 Impact |

|---|---|---|

| IoT Sensors | Real-time monitoring | 40% downtime reduction |

| AI Prediction | Auto-adjustments | 25% throughput boost |

| Full Automation | Energy efficiency | 30% lower power use |

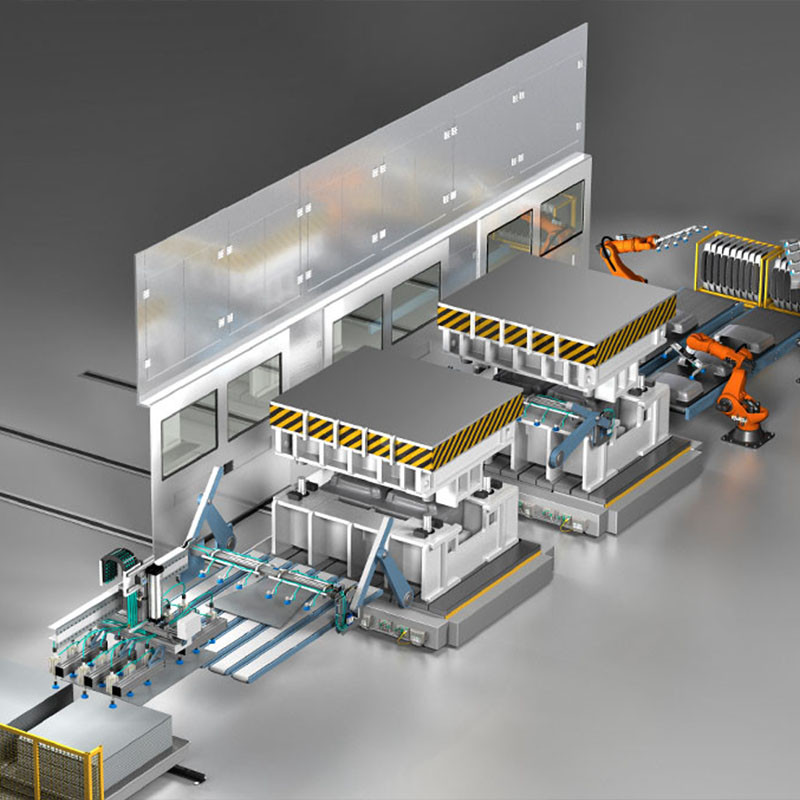

Fanty: Bringing Smart to the Everyday Line

After testing the waters with early IoT add-ons that felt bolted-on, Fanty's smart coil feeding lines hit different—baked-in sensors and AI lite that predict uncoiler slips without the $100K tag, all for lines feeding 5-20 ton coils at 30m/min.

Level Up Your Line: From Smart to Smarter

Industry 4.0's innovations like IoT and AI are making coil feeding lines smarter than ever in 2025—less guesswork, more gains, and lines that adapt like they read the blueprint. I've watched shops go from firefighting to flowing; what's the first tweak on your wishlist—sensors or servos? Drop it below; I've got pointers from the pit.

Line ready for smart? Reach out to Fanty for an Industry 4.0 coil feed audit. Innovate without the invoice shock.

By Alex Rivera, Line Innovator & 4.0 Evangelist | November 19, 2025