What Are the Top Challenges in Steel Coil Processing and How Do Decoilers Solve Them?

- Share

- Issue Time

- Jan 19,2026

Summary

Uncover the biggest hurdles in steel coil processing—like binding, tension inconsistencies, and edge defects—and how decoilers provide reliable fixes for efficiency and quality.

What Are the Top Challenges in Steel Coil Processing and How Do Decoilers Solve Them?

Posted on January 19, 2026 | By Tom Rivera, Coil Processing Consultant at Fanty Machinery

Steel coil processing keeps the backbone of manufacturing humming—automotive frames, appliances, construction beams—but it's riddled with headaches that can halt lines and balloon costs. I've troubleshooted enough jammed-up mills to know: Issues like binding, uneven tension, and edge defects aren't just annoyances; they drive up scrap by 15-20% and downtime by hours per shift.

Challenge 1: Coil Binding and Jamming—And Decoiler's Quick Release

Nothing grinds a line to a halt like a coil that won't unwind—damaged edges, poor lube, or excess tension cause binding, spiking scrap and safety risks.

Challenge 2: Tension Inconsistencies Causing Material Warp—Decoilers' Steady Hand

Uneven pull warps sheets, leading to die jams and off-spec parts—especially with variable-gauge steel where slack or over-tension ruins flatness.

Challenge 3: Edge Defects and Waste from Slitting—Decoilers' Clean Edge

Slit coils often arrive with waves, camber, or burrs, inflating waste and downstream defects in processing.

Challenge 4: Downtime from Packaging Damage and Handling—Decoilers' Gentle Grip

Battered packaging leads to inner coil damage, causing uncoil snarls and safety hazards in handling.

Challenge 5: Straightening Set and Creases Post-Uncoil—Decoilers' Level Play

Coils retain "memory" bends from rolling, creasing ends and feeding issues into dies.

Real Mill Makeover: Tackling Coil Chaos with Decoiler Smarts

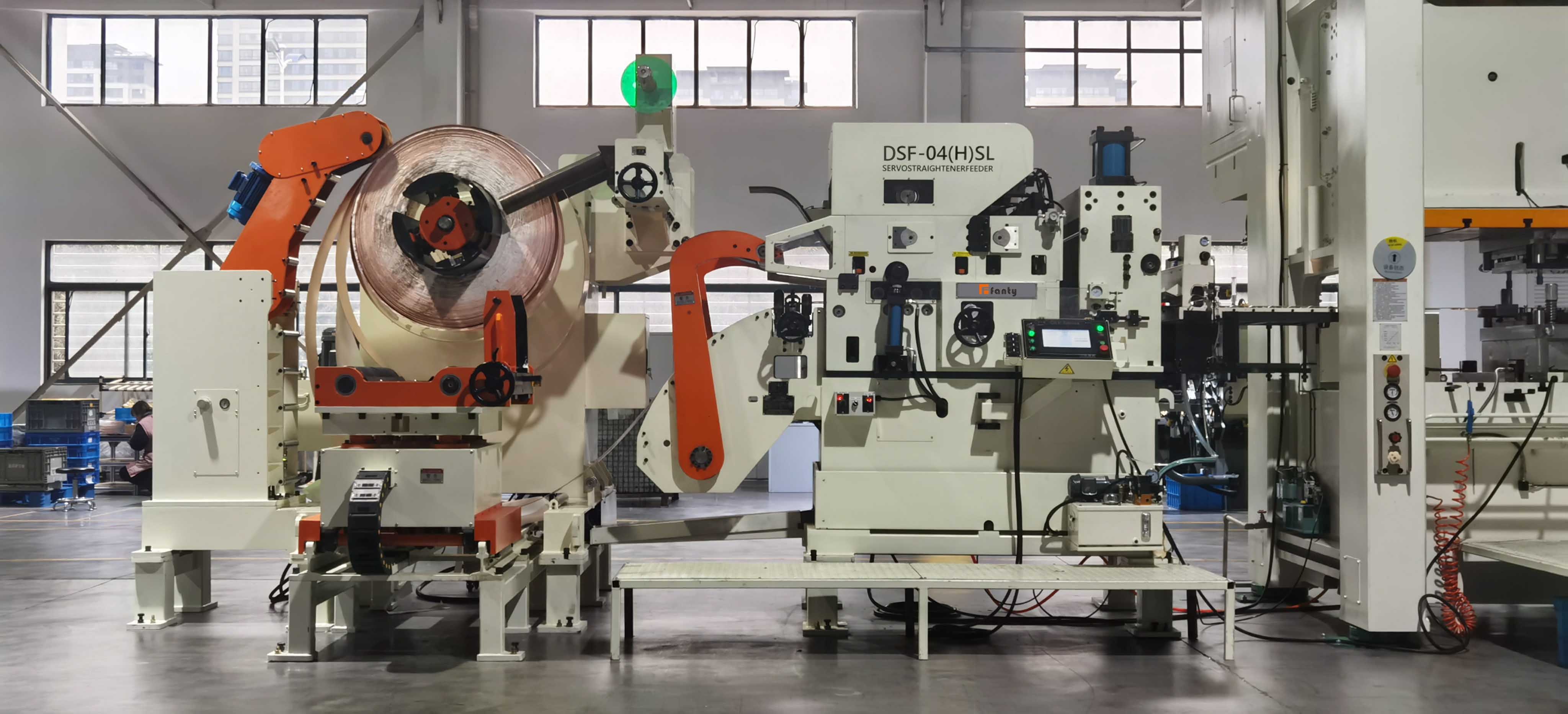

Picture a Ohio steel fab last fall: Binding and tension woes jacked scrap to 18%, lines idling 4 hours daily. We deployed a Fanty decoiler—boom, flatness hit 99%, downtime plunged 60%, and yields climbed. It's the everyday magic at Fanty Machinery, where since 2013 in Dongguan, our 45,000㎡ team of 370 (80 R&D pros) has solved these for 2,000+ ops, from BYD's volume beasts to U.S. mills. CE-certified with Delta controls, our decoilers don't just unwind—they unlock efficiency. See the full story on our About Us page.

Solve Your Coil Conundrums with Fanty: Precision Uncoiled

Why fight steel solo when Fanty's decoilers turn top challenges into triumphs? From hydraulic heavy-hitters to integrated straightener combos, we've got the fix for your processing pains—global-ready, downtime-proof. As your go-to for seamless steel flow, we're primed for audits and quotes. Grab a free coil challenge assessment today—let's straighten your ops.

Frequently Asked Questions

Q: How does a decoiler prevent coil binding?

A: Via adjustable tension and anti-friction designs—reduces incidents by 70% in steel lines.

Q: What's the ROI on a decoiler upgrade?

A: Often 6-9 months through waste cuts and uptime gains—proven in our installs.

Q: Can Fanty tailor for my steel gauge?

A: Yes—from thin sheet to heavy plate, with custom rolls for your exact needs.