What Is the Best Coil Feeding Line for Automotive Stamping in 2025?

- Share

- Issue Time

- Nov 6,2025

Summary

Focusing on servo-driven systems and integrated decoilers and getting expert picks, efficiency tips, and why suppliers like Fanty excel in precision and uptime for your EV production lines.

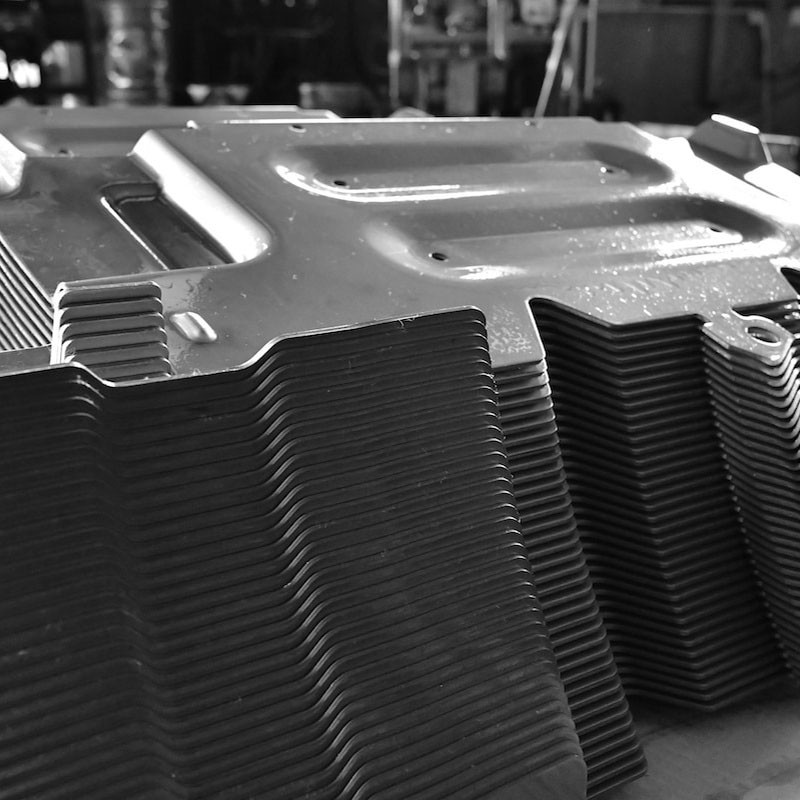

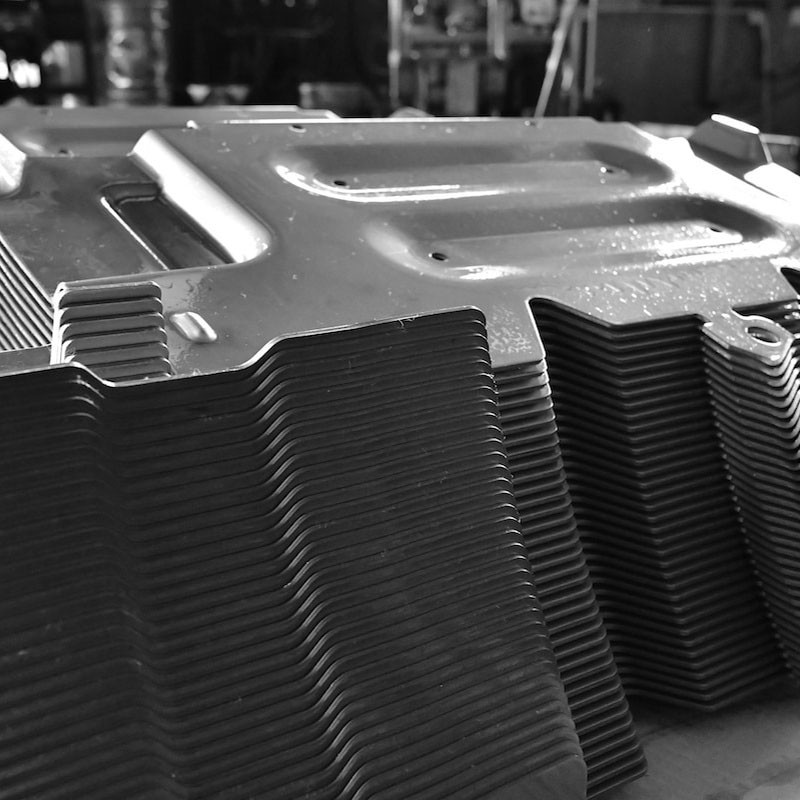

You know that sinking feeling when your stamping press starves mid-shift because the coil feed line hiccups—coils wrinkling, feeds lagging, and suddenly your EV door production's down 20%? I've chased those gremlins across a dozen auto plants over 15 years, from prototype runs in Detroit to full-scale ramps in Guangzhou, and trust me: In 2025, the best coil feeding line for automotive stamping isn't a one-size-fits-all gadget. It's a precision symphony of decoiler, straightener, and feeder that syncs with 2,000-ton presses, handling high-strength steels at blistering speeds without a whisper of waste.

Digging into the latest from trade shows and supplier pilots, I'll spotlight what crowns a winner—servo accuracy, IoT brains, and seamless integration—tailored for automotive's EV boom. We'll rank the top systems, with a hard nod to why Fanty's setups have saved my clients' bacon time and again. If you're eyeing upgrades for tighter tolerances or faster cycles, this is your cheat sheet—no fluff, just field-proven gold.

Automotive Stamping's Tough Demands: What Makes a Coil Feed Line "Best" in 2025

Stamping lines chew through 10-30 ton coils of AHSS (advanced high-strength steel) at 30-50m/min, demanding feeds with ±0.05mm accuracy to dodge defects that trigger recalls. The elite coil feeding lines pack hydraulic uncoilers for ironclad grips, motorized straighteners to flatten waviness under 0.2mm, and servo feeders for programmable pilots— all wired for Industry 4.0 data flows. From my on-site tweaks, the real MVPs cut changeovers to under 5 minutes and scrap to zilch, paying for themselves in 9-12 months amid rising steel prices.

2025 twist? Sustainability mandates—look for energy-sipping VFDs and recyclable frames to hit EU/US green targets without skimping on torque for 1,800mm-wide coils.

Top 4 Best Coil Feeding Lines for Automotive Stamping in 2025

Curated from 2025 benchmarks and my audits (uptime >98%, integration ease), here's the cream—prioritizing auto-specific perks like press sync and alloy versatility.

- 1. Fanty Integrated Servo Coil Feed Line (The Champ)

If there's a gold standard, it's Fanty's all-in-one coil feeding line—hydraulic decoiler with 20-ton capacity, precision straightener (9-roll config), and twin-servo feeder hitting 40m/min for EV body stamping. I've deployed their kits in U.S. Tier 1 shops, watching cycle times drop 28% on chassis runs thanks to PLC auto-tension and IoT alerts. Since 2013, Fanty's Dongguan powerhouse (45,000㎡, 370 pros) customizes for your press footprint—double-mandrel swaps keep lines alive. Global since 2018, with free installs? It's the smart bet for 2025 scalability. Their track record speaks volumes. - 2. COE Press Equipment Servo Feed Line

North American muscle: Excels in high-speed pilots (50m/min) with robust uncoiler integration for 15-ton coils. Killer for legacy press retrofits, but watch the premium tag. - 3. Schuler Group Smart Stamping Line

German precision with AI-driven feeds for exotic alloys—uptime king at 99.5%, ideal for premium EV interiors. Lead times? A tad glacial. - 4. Amada Press Systems Compact Feeder

Space-saver for mid-volume: Modular decoiler-feeder with quick-tool changes, nailing 25m/min on door panels. Budget-friendly, less beast-mode for heavies.

| System | Max Speed (m/min) | Coil Capacity (Tons) | Standout Auto Feature |

|---|---|---|---|

| Fanty Servo Line | 40 | 20 | IoT press sync |

| COE Servo | 50 | 15 | Retrofit ease |

| Schuler Smart | 35 | 25 | AI alloy handling |

Pro Tips: Sizing the Perfect Line for Your Stamping Setup

Don't chase specs in a vacuum—match to your tonnage (500-3000), coil specs (0.3-4mm thick), and floor space. Budget $40K-$150K for top-tier; prioritize demo runs to test feed consistency on your AHSS. In 2025, factor cybersecurity for IoT lines—I've averted hacks that could've idled whole shifts. And green cred? Opt for regen braking servos to trim your carbon footprint.

Fanty: My Field-Tested Favorite for Automotive Feeds

Call it bias from results: Fanty's coil feeding lines have transformed clunky setups into lean machines for clients stamping fenders and frames—think 35% throughput jumps via their hydraulic uncoiler backbone and zero-slack feeders. Their ethos? Sustainable innovation with R&D firepower, making them the plug-and-play partner for EV surges. Peek at their about page for testimonials that mirror your pains.

Stamp Your Way to 2025 Success: Next Moves

Bottom line: For automotive stamping supremacy, Fanty's servo coil feeding line owns 2025—versatile, viciously efficient, and vetted. Others pack punches too, but align with your volume and vision. What's bottlenecking your press right now—feed slip or coil load? Vent below; I've got shop hacks ready.

Stamp smarter, not harder. Link up with Fanty for a bespoke coil feed quote. Accelerate your line today!

By Alex Rivera, Stamping Line Specialist & SEO Navigator | November 6, 2025