Uncoiling Innovation: Advancements in Decoiler Technology

- Share

- Issue Time

- Nov 30,2023

Summary

This article delves into the latest advancements in decoiler technology, showcasing how innovation is transforming the metal processing landscape.

In the ever-evolving landscape of metal processing, the decoiler plays a pivotal role as the gateway to efficient production. This article meticulously examines the recent advancements in decoiler technology, shedding light on how innovation is reshaping the uncoiling process and driving unprecedented efficiency across diverse industries.

Introduction:The Crucial Role of Decoiler Technology

Commencing with a fundamental understanding of the significance of decoilers in metal processing, we delve into how technological advancements have elevated their role beyond simple unwinding mechanisms. Decoilers are no longer mere components but technological marvels driving precision and efficiency.

Key Technological Advancements

*Automation Integration:

Explore how automation seamlessly integrates into decoiler technology, enabling precise material handling and minimizing the need for manual intervention. This not only enhances efficiency but also contributes to a safer working environment.

*IoT and Real-Time Monitoring:

Uncover the impact of Internet of Things (IoT) in decoiler technology, allowing real-time monitoring of performance metrics. Predictive maintenance based on data-driven insights ensures optimal operation and reduces downtime.

Precision Unwinding for Diverse Materials

*Material Compatibility Enhancements:

Examine how recent innovations cater to a broader range of materials, from lightweight alloys to heavy-duty steel. Advanced decoiler technology ensures compatibility with diverse materials, contributing to versatility in metal processing.

*Width and Diameter Adjustments:

Highlight the importance of customizable width and diameter adjustments, allowing decoilers to handle various coil sizes. This adaptability is crucial for accommodating different materials and coil dimensions.

Applications Across Industries

*Automotive Manufacturing:

Understand how advancements in decoiler technology benefit the automotive sector, ensuring precision in handling materials for the production of components ranging from body panels to intricate parts.

*Aerospace Engineering:

Explore the role of decoilers in aerospace engineering, where the demand for precision is paramount. Technological innovations contribute to the efficient processing of specialized alloys used in aerospace components.

Environmental and Cost-Efficiency Considerations

*Reduced Material Waste:

Discuss how modern decoiler technology minimizes material waste through precise unwinding, contributing to environmental sustainability and cost-efficiency.

*Energy-Efficient Operation:

Highlight energy-efficient features in advanced decoilers, emphasizing their contribution to sustainable and cost-effective metal processing operations.

What Decoiler/Uncoiler Does Fanty Manufacture?

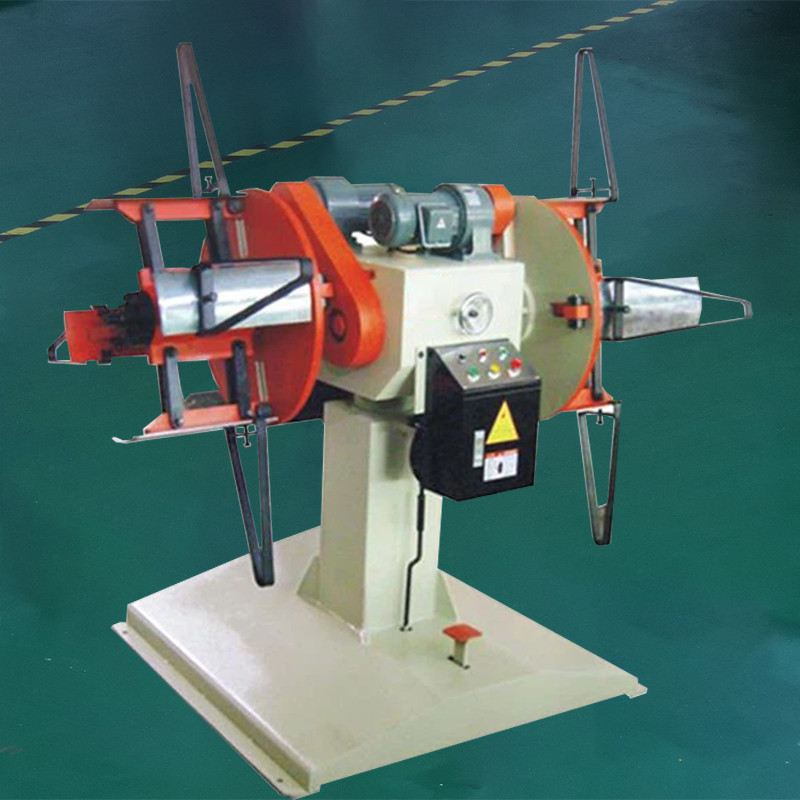

Designed for narrow width coil unwinding, capable of handling a range of materials and coil sizes and suit for high speed punch line.

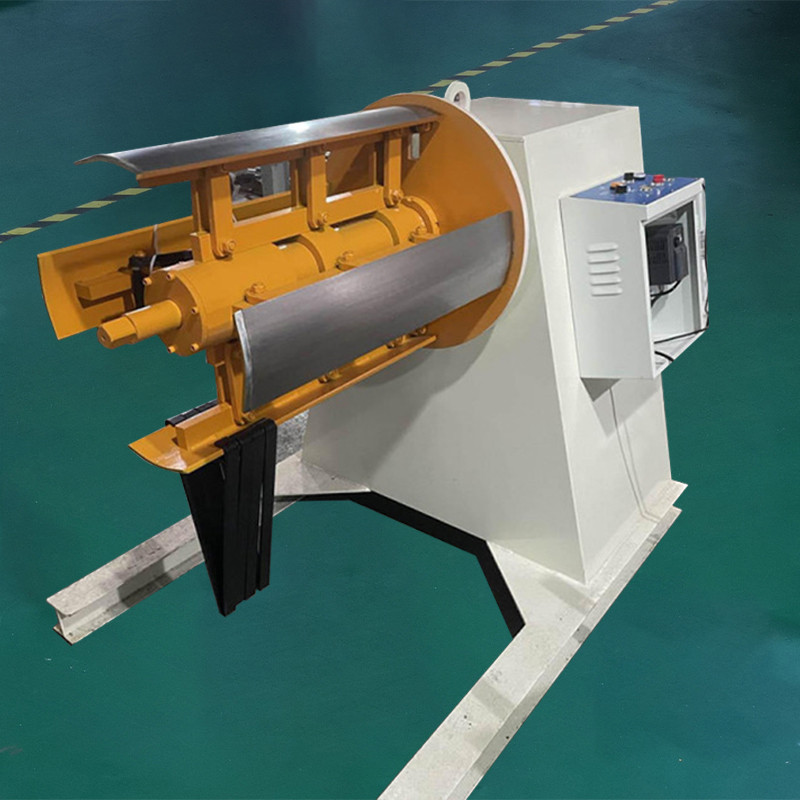

Designed with a hydraulic mechanism that provides accurate control during unwinding and can effectively handle big coils.

Designed to withstand heavy loads and larger coils, offering dependable performance and stability.

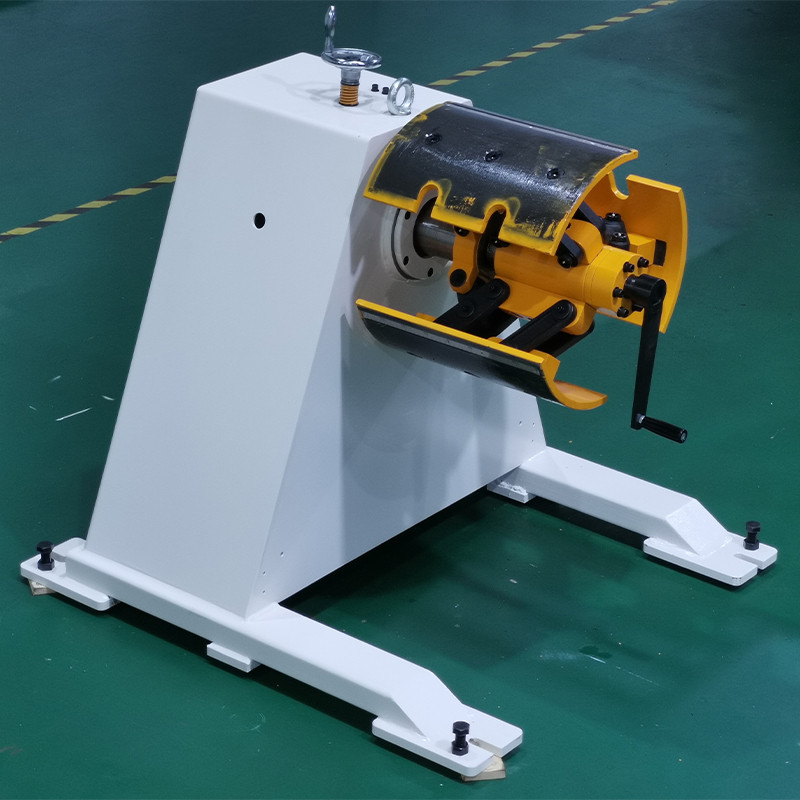

Manually operated; ideal for workshops or smaller-scale applications where coil handling occurs occasionally.

Conclusion