Things to think about before purchasing a decoiler

- Share

- Issue Time

- Dec 28,2023

Summary

When purchasing a decoiler in the stamping market, consider factors such as the type of decoiler needed, brand reputation, and pricing.

What aspects need to be taken into account while purchasing a decoiler?

The stamping market is currently filled with a wide variety of decoiler types, brands, and prices. What aspects of this situation should stamping buyers take into account before making a decoiler machines purchase?

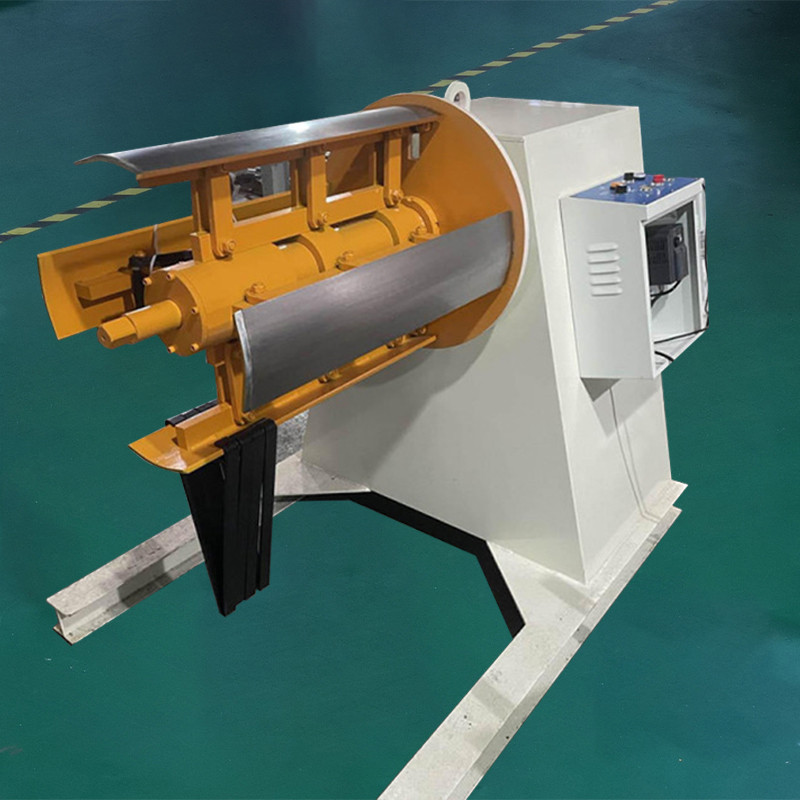

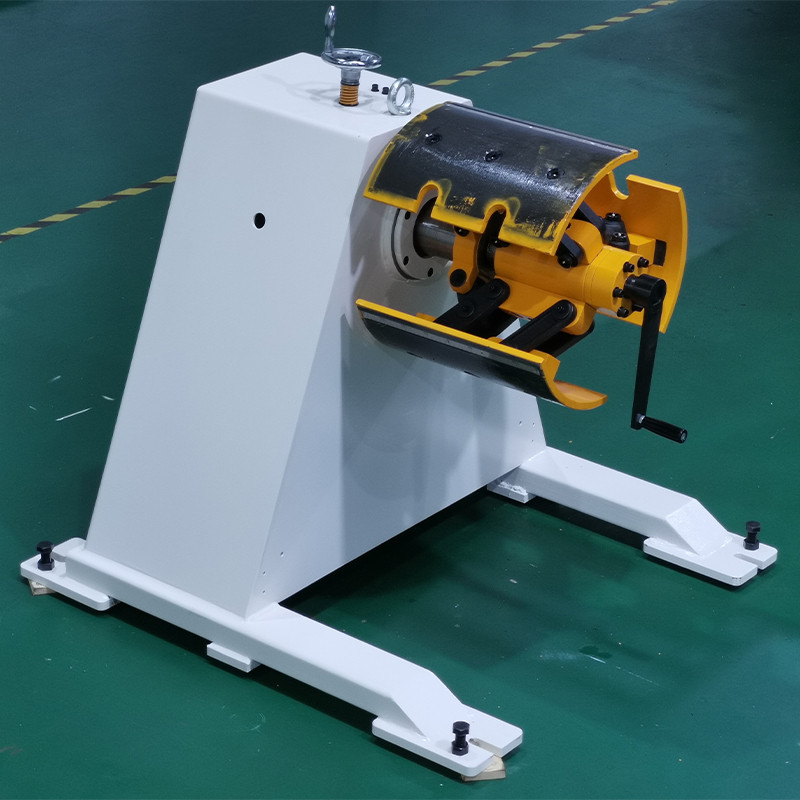

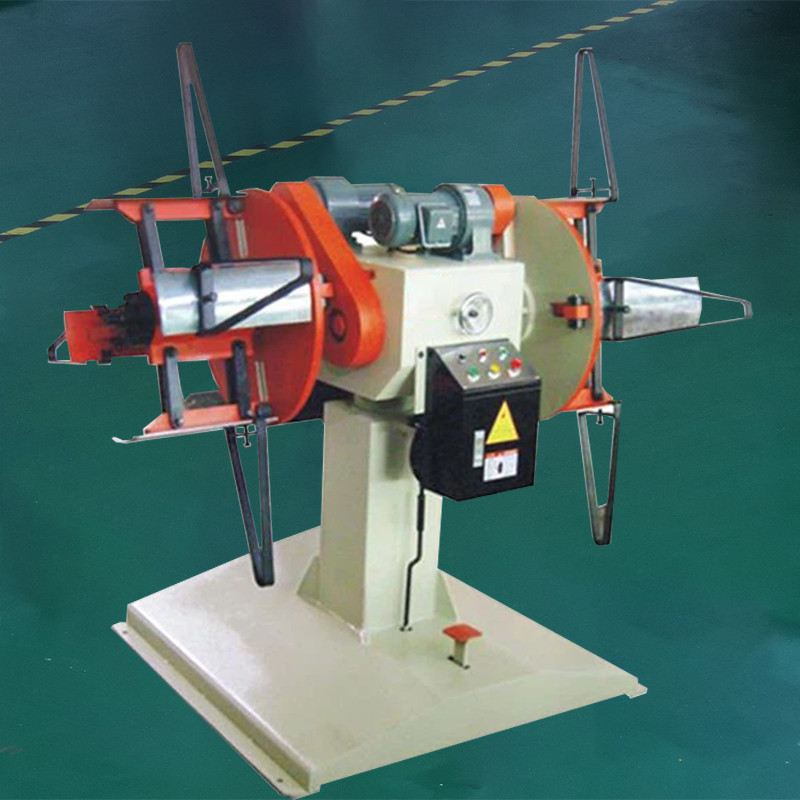

Choose the kind of decoiler you require first. Decoiler machines come in five varieties. This page explains how the five distinct categories are divided.

All inquiries concerning uncoilers and decoilers can be found Here.

1. Prior to making a purchase, stamping clients must ascertain the stamping materials' breadth, thickness, inner diameter, outer diameter, weight, and production line speed. They should then choose the necessary optional devices based on their specific requirements.

2. It is contingent upon the decoiler's brand. The stamping automation sector is currently a somewhat mature one. Mature sectors are distinguished by well-established brands and reliable, effective machinery. Customers must thus select well-known brands and manufacturers when selecting a decoiler; for instance, select our FANTY.

3. It is contingent upon the decoiler's cost. FANTY has always focused on two things: cutting management expenses and returning customers' faith and support. FANTY constantly guarantees favorable and satisfied bids to customers while guaranteeing the quality of the decoiler, enabling them to purchase a high-quality decoiler at a reasonable cost.

Being a skilled producer of decoiler machines, FANTY can provide stamping clients a range of standard decoiler machines in addition to customizing different models to meet their specific requirements. These specially designed models are not restricted to load increases, inner and outer diameter changes, frequency conversion control, etc.; rather, they are expertly designed and tailored to meet the demands of clients, thereby optimizing the efficiency of their stamping production.

The aforementioned is a list of safety precautions when utilizing the uncoiler. For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder