Common Issues with Soft Material Uncoiler Rewinding

- Share

- Issue Time

- Jan 2,2024

Summary

The uncoiler, a staple in the stamping industry, serves not only for uncoiling but also for rewinding processed strips or scraps.

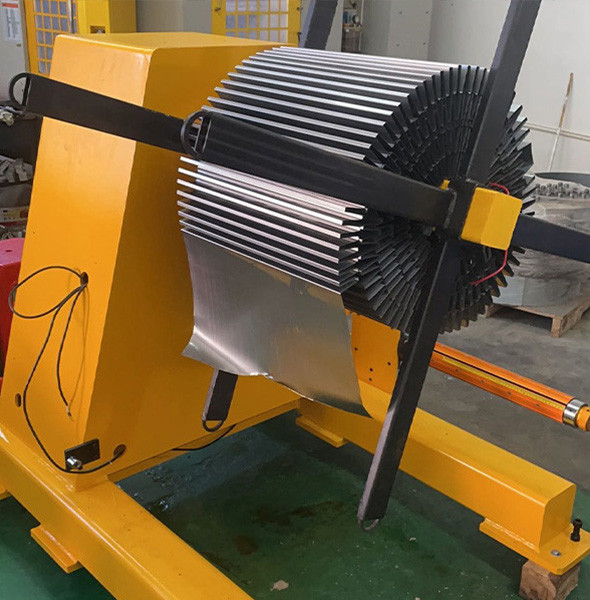

The decoiler is also called uncoiler as a steel coil handling equipment. In addition to being used for uncoiling, the uncoiler is also frequently employed in the stamping industry for rewinding finished strips or waste following processing as a recoiler.

Difference between decoiler and recoiler

The only thing required to replace the unwinding induction rod for conventional metal coils is switching to an induction frame or a photoelectric induction device. The uncoilers used for uncoiling and recoiler differ very little. However, there are some soft materials where rewinding and uncoiling are very different.

Because if the soft material is not tensioned when used for rewinding, it will have an impedance effect and become extremely rigid when exporting. The accuracy and quality of the final product will be significantly impacted by the phenomena of width shrinkage and deformation, which can easily happen when the tension is excessively tight.

Therefore, the stamping industry has long been working to solve the technological problem of how to modify the uncoiler to make it as a recoiler rewinding soft materials more smoothly.

Installing a guiding tensioning mechanism on the uncoiler during the winding process to aid in the efficient rewinding of soft material is now the most widely used and successful technique in the stamping industry. On the uncoiler, there are two primary categories of guidance device installations.

1. Pulling is used to directly tension the rewinding material. However, in this type of material guide device, the rewinding material will occasionally be stretched and occasionally return to slack, resulting in an unstable state, when the material used to guide the material possesses both soft material and elasticity. Because of this, deformation mistakes in the uncoiler can have an impact on the quality of the rewinding.

2. To ensure that the material is guided with the proper tightness, a dampening device is installed on the uncoiler's material guiding device. Nonetheless, this structural layout can lessen the material's pulling and jittering phenomena and steady the material's directing. It is nevertheless simple to pull the material excessively tightly, retract it, and distort it due to the strong resistance created by the damping device mounted on the decoiler to the rotation of the guide device. Furthermore, the issue of how the accuracy and caliber of the final rewinding goods are impacted cannot be resolved by this.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder