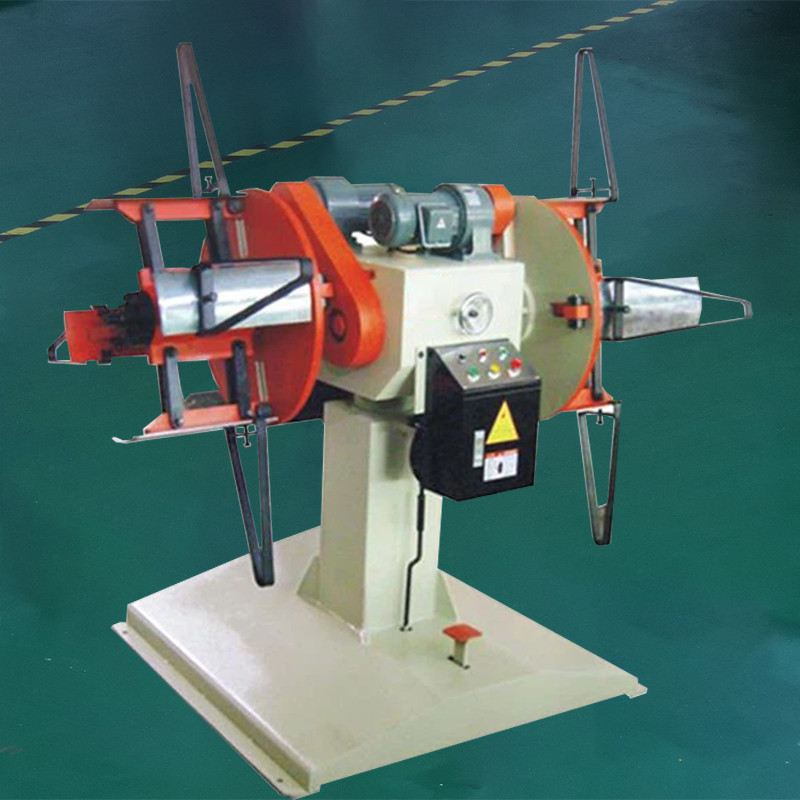

The ideal choice for continuous uncoiling work is a double head uncoiler

- Share

- Issue Time

- Jan 4,2024

Summary

The double-head uncoiler revolutionizes stamping automation by minimizing downtime during coil changes, enhancing overall production efficiency.

A double head uncoiler is the most efficient choice for continuous uncoiling tasks.

The packaged coils must be used in stamping automation production, and before they can be used, the coils must be uncoiled by the uncoiler. Conventional decoilers employ a single roll to hold the coil material, and when that roll is empty, the entire production line apparatus must be stopped. Reloading and debugging the uncoiler takes a lengthy time, which is not only laborious but also prevents the stamping production line's total efficiency from being increased.

This issue is essentially resolved with the introduction of the double-head uncoiler, which also includes a discharge reel in addition to the standard uncoiler. One reel is turned to the uncoiling working position under the drive of the driving device on the rotating platform by positioning the two reels symmetrically on the rotary platform. At the same time, the operator can load the second reel. The latter reel of the uncoiler can rotate to the uncoiling position for uncoiling as soon as the first reel is uncoiled. The uncoiling efficiency is great, the continuity is good, the stable production period is extended, and the overall efficiency of the stamping production line is increased from the actual realization of uninterrupted uncoiling operation.

Consequently, the double-head uncoiler may improve stamping efficiency, cut down on needless time, and essentially solve the issue with the conventional decoilers. It goes without saying that selecting a double-head uncoiler will cost extra. Without going over budget, the conventional decoilers remain the best option for experienced operators.

In addition to its undeniable benefits, the double-head uncoiler also brings about a significant reduction in downtime during stamping automation production. Traditional single-roll uncoilers often lead to frequent interruptions when reloading, impacting the overall efficiency of the production line. The double-head uncoiler's innovative design, featuring two reels on a rotary platform, ensures a seamless transition between coils. This allows one reel to be actively uncoiling while the operator loads the other, ensuring a continuous and uninterrupted operation.

Furthermore, the double-head uncoiler not only optimizes efficiency but also extends stable production periods. This results in an overall improvement in the efficiency of the stamping production line. While the initial investment in a double-head uncoiler may be higher, the long-term benefits in terms of increased productivity and reduced downtime make it a cost-effective choice for stamping automation.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder