Enhancement of the non-powered uncoiler's brake structure

- Share

- Issue Time

- Jan 10,2024

Summary

Fanty introduces a revolutionary upgrade to non-powered uncoilers, addressing traditional challenges in stamping production.

Introduction of Uncoiler

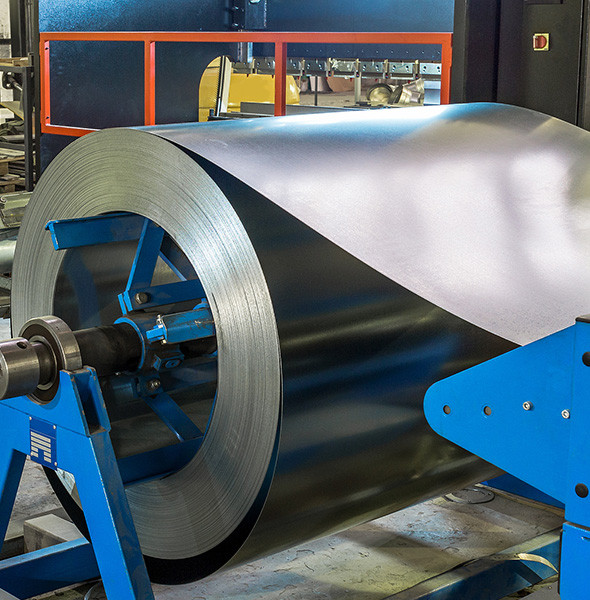

In the realm of stamping production, as the steel coil handling equipment, uncoiler plays a pivotal role, facilitating the seamless progression of materials for various applications. While powered decoiler is more commonplace, non-powered decoiler holds significant value, particularly in scenarios demanding a reduction in floor space. Fanty, recognizing the inherent limitations of traditional non-powered decoiler, has undertaken groundbreaking enhancements to revolutionize the braking mechanism, ensuring optimal efficiency in stamping processes.

Non-Powered Uncoiler Basics:

Non-powered uncoiler finds application in specific stamping scenarios such as shelves, motors, and EI sheets. Traditionally, the material roll is manually introduced onto the supporting material tile, and the material head is manually pulled into the coil leveling machine. The rotation of the material roll is synchronized with the feeding of the coil leveling machine. However, a critical challenge arises when the feeding stops—the inertia-driven rotation of the supporting tile continues, necessitating the integration of an effective braking device to prevent material scattering.

Challenges in Traditional Non-Powered Uncoiler:

The discontinuous nature of the coil leveling machine's feeding process, occurring at high frequencies, poses a significant challenge for traditional non-powered uncoiler. The existing braking devices struggle to achieve alternating high-speed braking and loosening of the supporting tile, limiting their efficiency in automated stamping production.

Fanty's Innovative Solution:

Fanty has undertaken a comprehensive redesign of the braking device for non-powered uncoilers, addressing the shortcomings of traditional systems. The enhanced design involves the integration of upper and lower brake levers that rotate along the brake bracket through the expansion and contraction of the cylinder. During cylinder contraction, the upper and lower friction plates tightly grip the brake disc, bringing the supporting tile to an immediate halt and preventing material disarray. Conversely, cylinder extension releases the brake disc, enabling the supporting tile to rotate and achieve automatic uncoiling.

Benefits for Automated Stamping Production:

Fanty's innovative non-powered uncoiler design ensures alternating high-speed braking and loosening of supporting tiles, aligning seamlessly with the demands of automated stamping production. This breakthrough significantly improves efficiency, mitigates material scattering issues, and fulfills the evolving needs of manufacturers in the stamping industry. Learn more Automated Stamping Solution, pls refer: https://www.decoilerfeeder.com/comm06/Automatic-Stamping-Production-Line.htm

Conclusion:

Fanty's commitment to pushing the boundaries of innovation in the uncoiling domain has resulted in a transformative solution for non-powered uncoilers. The refined braking mechanism stands as a testament to Fanty's dedication to enhancing operational efficiency in stamping processes, offering manufacturers a cutting-edge solution for their diverse production needs.

For any questions, you can get in touch with us directly at fanty@sz-fanty.com, and we'll help you figure out the problem.

Follow FANTY Channel:

Youtube: https://www.youtube.com/@fantydecoilerfeeder

Facebook: https://www.facebook.com/Fanty1229/

Linkedin:https://www.linkedin.com/company/fantydecoilerfeeder