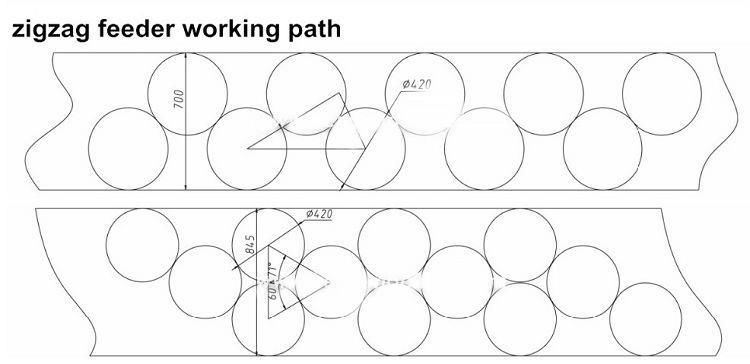

Precision Zig Zag Servo Feeder Machine for Circle Stamping Blanking Line

- Model

- NCP Series Precision Zig Zag Servo Feeder Machine

Item specifics

- Color

- Standard white (other colors are available)

- Payment

- 30% T/T as deposit, rest against shipping

- Certificate

- ISO, CE

- Customized Service

- Yes

Review

Description

* Mitsubishi PLC

* Yaskawa servo motor

* WEINVIEW Touch Screen

Model | NCP-200 | NCP-300 | NCP-400 | NCP-500 | NCP-600 | NCP-800 |

Coil Width | 165° | 140° | 165° | 140° | ||

Coil Thickness | 0.2-2.0 mm | |||||

Release | Pneumatic Type Releasing System | |||||

Roll Pressure | Spring Type | |||||

Feed Roll | Upper Roll 1pc, Bottom Roll 1pc | |||||

Feed Length | Max. 9999.99 mm | |||||

Speed | Feeding Speed Max. 20 m/min, Zigzag Movement Speed Max. 30 m/min | |||||

Left Center Displacement | 100mm | 150mm | 200mm | 250mm | 300mm | 400mm |

Servo Motor | Yaskawa, Japan | |||||

Servo Drive | Yaskawa, Japan | |||||

PLC | Mitsubishi, Japan | |||||

Touch Screen | Weinview, Taiwan | |||||

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

We manufacture decoiler, leveler, coil feeder, decoiler straightener 2 in 1, decoiler straightener feeder 3 in 1, We also sale press punch like high speed punch press, precision punch press, cut to length line, slitting line, roll forming machine.

We accept T/T and L/C Payment.

30% deposit, 70% balance before delivery.

Pneumatic feeder

NC servo feeder

High speed roller feeder

High speed gripper feeder

etc

1. For simple machine, decoiler, leveler, coil feeder, decoiler straightener 2 in 1, we have manual to help user how to make installation and operation.

Also we can provide video to help user make installation.

2. For press feeding system, Automatic decoiler straightener feeder 3 in 1, we will provide detail manual, we also provide oversea installation and operation training if need.