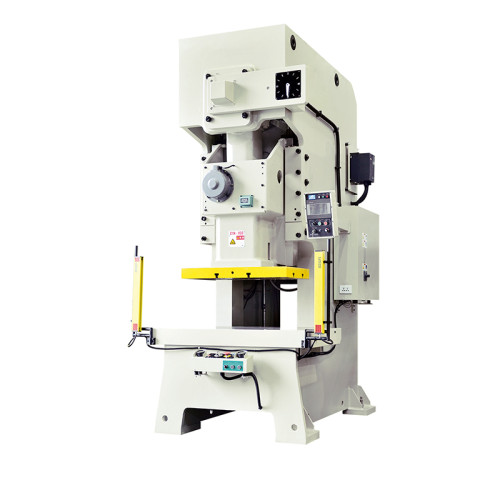

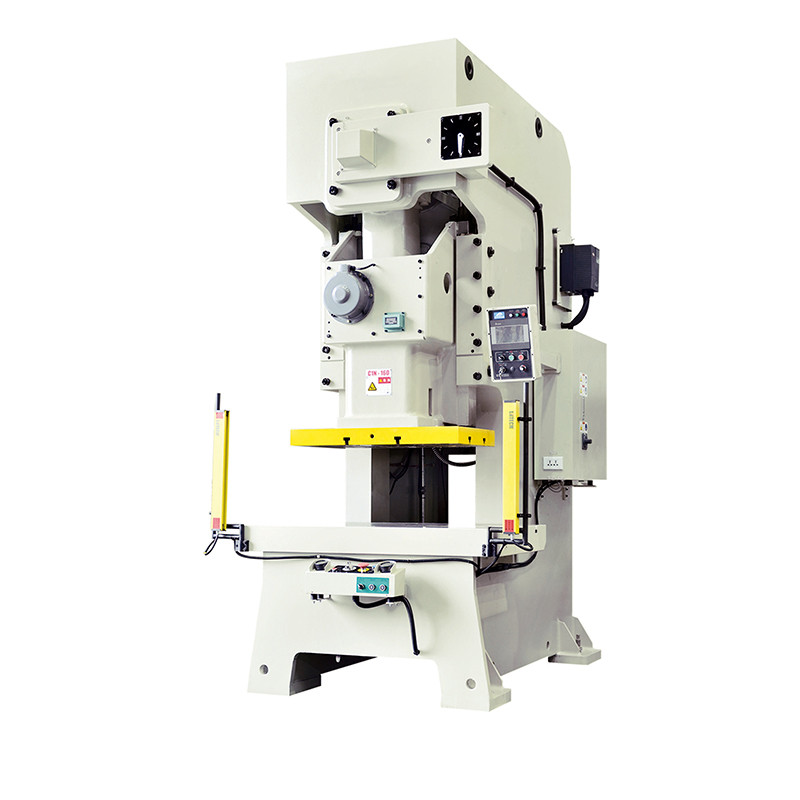

High-Precision Punch Press for Auto Part Stamping

- Model

- C1N Series High-Precision Punch Press

Item specifics

- Color

- Standard white (other colors are available)

- Payment

- 30% T/T as deposit, rest against shipping

- Customized Service

- Support

Review

Description

Precision Punch press refers to a specialized tool used in metal stamping and fabrication processes to create precise holes, shapes, or patterns in various materials. This high-accuracy tool is designed with precision engineering and manufacturing techniques to ensure consistent and accurate results. Precision punches are commonly used in industries such as automotive, aerospace, electronics, and manufacturing, where tight tolerances and intricate designs are required. With their sharp cutting edges and superior craftsmanship, precision punches provide reliable performance and contribute to the production of high-quality components and products.

C1N-15 | C1N-25A | C1N-25 | C1N-35 | C1N-45 | C1N-60 | C1N-80 | ||||||

V | V | V | H | V | H | V | H | V | H | V | H | |

Nominal Pressure (Kn) | 150 | 250 | 250 | 350 | 450 | 600 | 800 | |||||

Variable Stroke Per Minute (s.p.m) | 120~180 | 60~140 | 60~140 | 130~200 | 40~120 | 110~180 | 40~100 | 100~150 | 35~90 | 80~120 | 35~80 | 80~120 |

Fixed Stroke Per Minute (s.p.m) | 130 | 110 | 110 | 85 | 75 | 65 | 65 | |||||

Stroke (mm) | 60 | 80 | 60 | 30 | 70 | 40 | 80 | 50 | 120 | 60 | 150 | 70 |

Die Height (mm) | 200 | 195 | 200 | 215 | 220 | 235 | 250 | 265 | 310 | 340 | 340 | 380 |

Slide Adjustment (mm) | 50 | 50 | 50 | 55 | 60 | 75 | 80 | |||||

Slide Area (mm) | 300x230x50 | 360x250x50 | 400x300x60 | 500x360x70 | 560x420x70 | |||||||

Bolster Area (mm) | 680x300x70 | 680x300x70 | 680x300x70 | 800x400x70 | 850x440x80 | 900x500x80 | 1000x550x90 | |||||

Shank Hole (mm) | φ38.1 | φ38.1 | φ38.1 | φ38.1 | φ38.1 | φ50 | φ50 | |||||

slide Adjust Device | Manual Operation | |||||||||||

Motor (KW) | 2.2x6 | 4x4 | 4x4 | 4x4 | 5.5x4 | 5.5x4 | 7.5x4 | |||||

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

A: Yes, we provide comprehensive training programs for operating and maintaining our high precision punch press machines. Our experienced technicians will guide your operators on safe machine operation and routine maintenance practices.

A: Absolutely! Our high precision punch press machines are designed to be easily integrated into automated production lines. We offer various automation options, such as robotic loading and unloading systems, to enhance productivity and efficiency.

A: Our high precision punch press machines come with a standard warranty period of 12 months from the date of installation. We also offer extended warranty options and comprehensive after-sales support packages for your peace of mind.

A: To request a quotation, please visit our website or contact our sales team directly. We will need specific details about your application requirements to provide an accurate quotation.