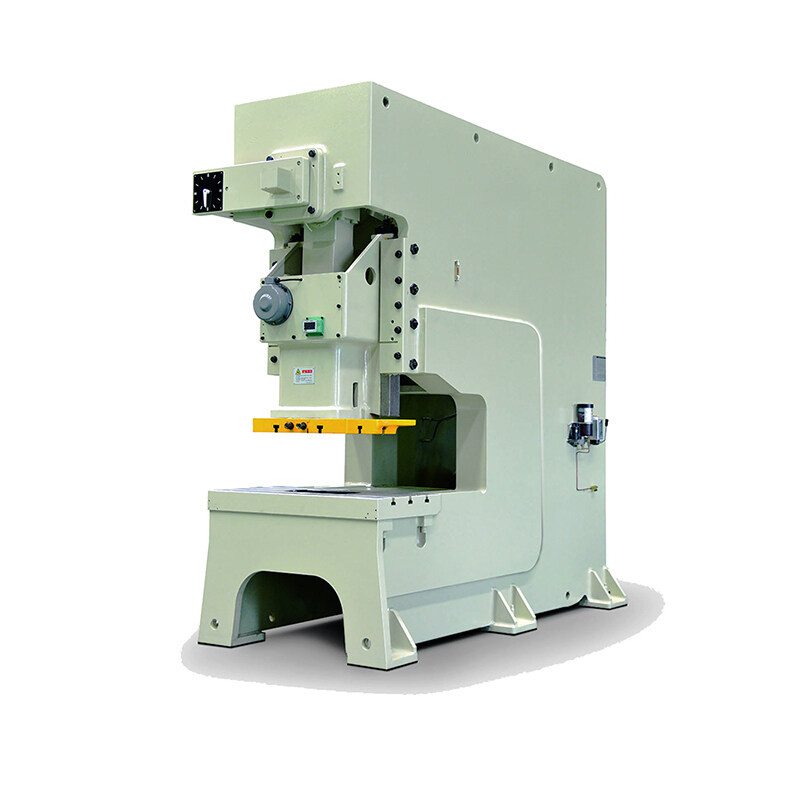

Precision Punch Press for High-Speed Metal Forming

- Model

- C1S Series High-Speed Metal Forming Press

Item specifics

- Color

- Standard white (other colors are available)

- Payment

- 30% T/T as deposit, rest against shipping

- Customized Service

- Yes

Review

Description

High-productivity precision punch press enables the creation of holes, shapes, or patterns in materials that require an extended reach. This punch press offers high precision, durability, and versatility, making it ideal for applications where standard punch presses cannot reach or accommodate specific design requirements. With its extended throat depth, the High-productivity precision press provides enhanced flexibility and efficiency in metal stamping and fabrication processes.

C1S-45 | C1S-60 | C1N-80 | C1S-110 | C1S-160 | ||||

V | V | V | H | V | H | V | H | |

Nominal Pressure (Kn) | 45 | 60 | 80 | 110 | 160 | |||

Rated Tonnage Point (mm) | 3.5 | 4 | 4 | 6 | 6 | |||

Variable Stroke Per Minute (s.p.m) | 40~100 | 35~90 | 35~80 | 30-60 | 20-50 | |||

Fixed Stroke Per Minute (s.p.m) | 75 | 65 | 65 | 50 | 35 | |||

Stroke (mm) | 80 | 120 | 150 | 180 | 200 | |||

Die Height (mm) | 250 | 310 | 340 | 360 | 460 | |||

Slide Adjustment (mm) | 60 | 75 | 80 | 80 | 100 | |||

Slide Area (mm) | 400x300x60 | 500x360x70 | 560x420x70 | 650x470x80 | 700x550x90 | |||

Bolster Area (mm) | 850x440x80 | 900x500x80 | 1000x550x90 | 1150x600x110 | 1250x800x140 | |||

Shank Hole (mm) | φ38.1 | φ50 | ∅50 | ∅50 | ∅65 | |||

slide Adjust Device | Manual operation, Electric driving | |||||||

Motor (KW) | 5.5x4 | 5.5x4 | 7.5x4 | 11x4 | 15x4 | |||

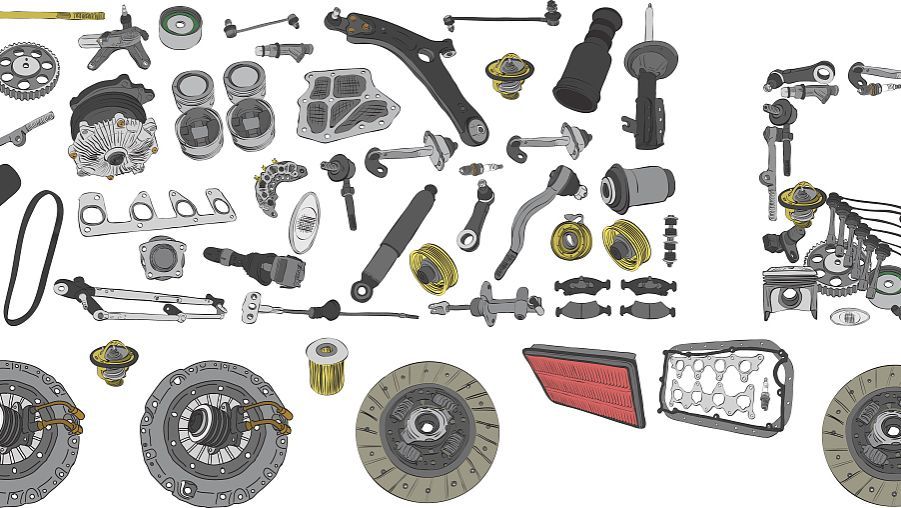

Fanty machinery focus on the domestic market of punch press automation equipment production and sales from 2013. The field including domestic hardware industry , automotive stamping line, auto metal stamping part, saw blade production, high speed rotor and stator stamping and lamination, eyelet stamping line and so on.

We provide high quality uncoiling, leveling, feeding and punch equipment to help many local factories realize the importance of automation production, and more and more factories upgrade and improve their metal stamping line. Fanty machinery has exported machine to more than 30 countries. MORE

A: Yes, we maintain an inventory of commonly used spare parts for our precision punch press machines. We can provide timely delivery of spare parts to minimize downtime in case of any maintenance or repairs.

A: To request a quotation, please visit our website or contact our sales team directly. We will need specific details about your application requirements to provide an accurate quotation.

A: Yes, our precision punch press machines are designed for continuous production operations. They are built to withstand heavy-duty usage and offer reliable performance for long production runs.

A: Our precision punch press machines are used in a wide range of industries, including automotive, aerospace, electronics, appliance manufacturing, and metal fabrication. They are versatile and can cater to various industry needs.